SpaceX’s new Raptor engine is a methane fueled full flow staged combustion cycle engine and it’s so hard to develop, no engine like this has ever flown before!

Now this topic can be really intimidating so in order to bring the Raptor engine into context, we’re going to do an overview of a few common types of rocket engine cycles then compare the Raptor to a few other common rocket engines, like SpaceX’s current work horse, the Merlin, The Space Shuttle’s RS-25, the RD-180, Blue Origin’s BE-4 and the F-1 engine.

And if that’s not enough, not only is SpaceX using a crazy engine cycle, they’re also going to be using Liquid Methane as their fuel, again something that no orbital rocket has ever used! So we’ll also go over the unique characteristics of liquid methane as a rocket fuel and see if we can figure out why SpaceX went with Methane for the Raptor engine.

We’ll also break down and explain all the different engine cycle types so you know what the full flow staged combustion cycle is, how it works, and how it compares to the other cycles.

So by the end of this article hopefully we’ll have the context to know why the raptor engine is special, how it compares to other rocket engines, why it’s using methane and hopefully find out if the Raptor engine will be the new king of rocket engines…

In case you didn’t notice when you clicked on this article… this is a VERY VERY long article… sorry, not sorry. BUT, if you’re anything like me, you keep hearing a lot of hype about the Raptor engine and you want to appreciate it… but you don’t even know where to start.

Well, I’ve spent quite a while really studying up on this subject so I can lay down a good foundation in order to help us fully appreciate the Raptor engine, well and quite frankly, all rocket engines!

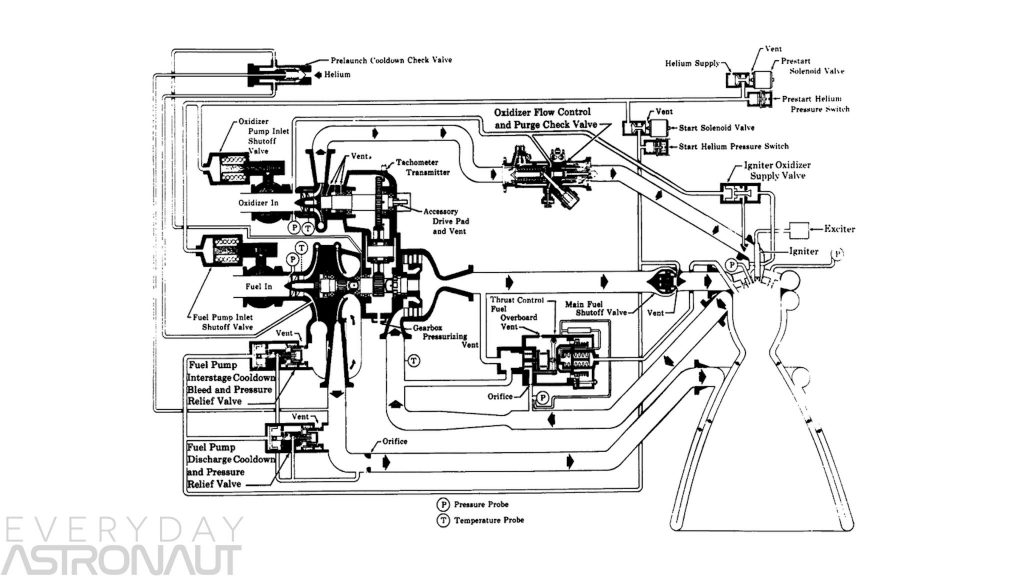

And if you’re anything like me, maybe you’ve stared at diagrams like this for hours and your head explodes every single time. So to avoid that, I’ve personally whipped up some very simplified versions of the rocket engine cycles for us all to enjoy, which will hopefully help us grasp these concepts.

Now we’re going to start with a super quick physics lesson, but bear with me, we’ll dive in and get plenty of nitty gritty details… we’ll leave no stone unturned and by the end of this article hopefully you’ll have a strong grasp of how rocket engines work, the different versions of liquid fueled rocket engines, why methane is a valid choice for fuel, and you’ll know exactly how the Raptor engine stacks up against some other popular rocket engines.

Rockets are basically just propellant with some skin around it to keep it in place and they have a thing on the back that can throw said propellant really really fast. And to way over simplify it even more, the faster you can throw that propellant, the better.

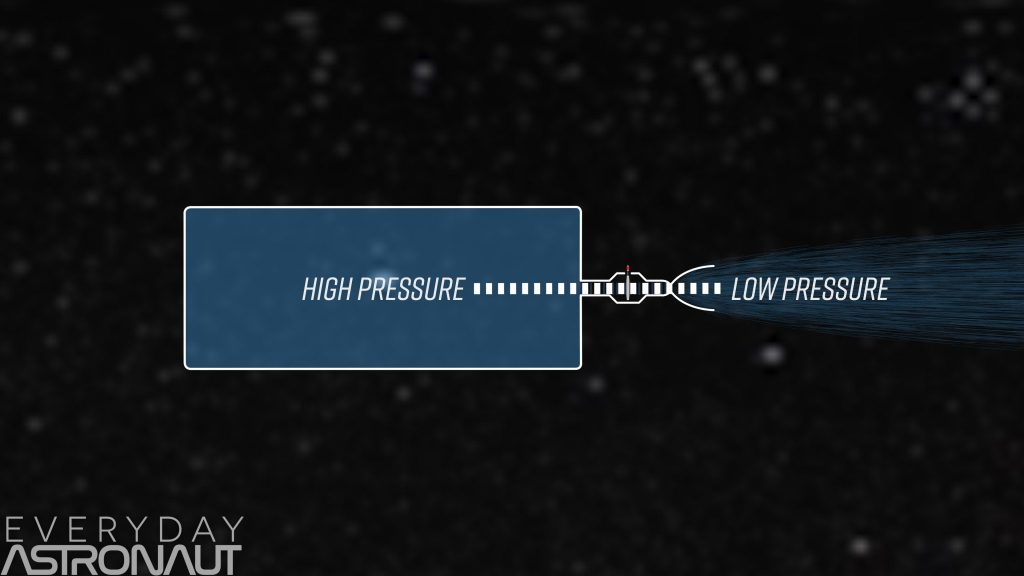

The easiest way to do this is by storing all the propellant in your tanks under really high pressure, then put a valve on one end of the tank and a propelling nozzle that accelerates the propellant into workable thrust. DONE! No crazy pumps, or complicated systems, just open a valve and let er rip.

This is called a pressure fed rocket engine and there’s a few main types; cold gas, monoprop and bipropellant pressure fed engines. You’ll often find these used for reaction control systems because they’re simple, reliable and quick.

But pressure fed engines have one big limiting factor. Pressure always flows from high to low, so the engine can never be higher pressure than the propellant tanks.

In order to store propellant under high pressure, your tanks will need to be strong and therefore thicker and heavier. Look at composite overwrapped pressure vessels or COPVs. They’re capable of storing gasses at up to almost 10,000 psi or about 700 bar.

Despite this, there’s still a limited amount of propellant and pressure they can store. This does not scale up very well when you’re trying to deliver a payload to orbit.

So smart rocket scientists quickly realized in order to make the rocket as lightweight as possible, there’s really only ONE thing they could do. Increase the enthalpy. That would be a great 90’s metal band name. You’re welcome internet.

Enthalpy is basically the relationship between volume, pressure and temperature. A higher pressure and temperature inside the combustion chamber equals higher efficiency and more mass shoved through the rocket engine equals more thrust.

So in order to shove more propellant into the engine, you could either increase the pressure in the tanks, or just shoot the propellant into the combustion chamber with a high powered PUMP. Huh, the second option sounds like a good idea!

But PUMPS moving hundreds of liters of fuel per second require a lot and boy do I mean a lot of energy to power them. So what if you took a tiny rocket engine and aimed it right at a turbine to spin it up really fast? You could exchange some of the rocket propellant’s chemical energy for kinetic energy which then could be used to spin these powerful pumps.

Welcome to turbopumps and the staged combustion cycle! But you’ve still got some limiting factors, like how high pressure always wants to go to low pressure and how heat has that habit of melting things… So you’ve got to keep all these factors in check while trying to squeeze every bit of power out of your engine.

Now there’s actually a lot of cycles here we could talk about, but I’m going to stick with the three most common, or at least the three that matter the most when putting the Raptor into context.

We have the gas generator cycle, the partial flow staged combustion cycle and lastly we’ll look at the full flow staged combustion cycle… and perhaps in a future article I’ll try and do a full rundown of all liquid fueled rocket engines including fun new alternatives like the electric pump fed engines seen on Rocket Lab’s Electron rocket.

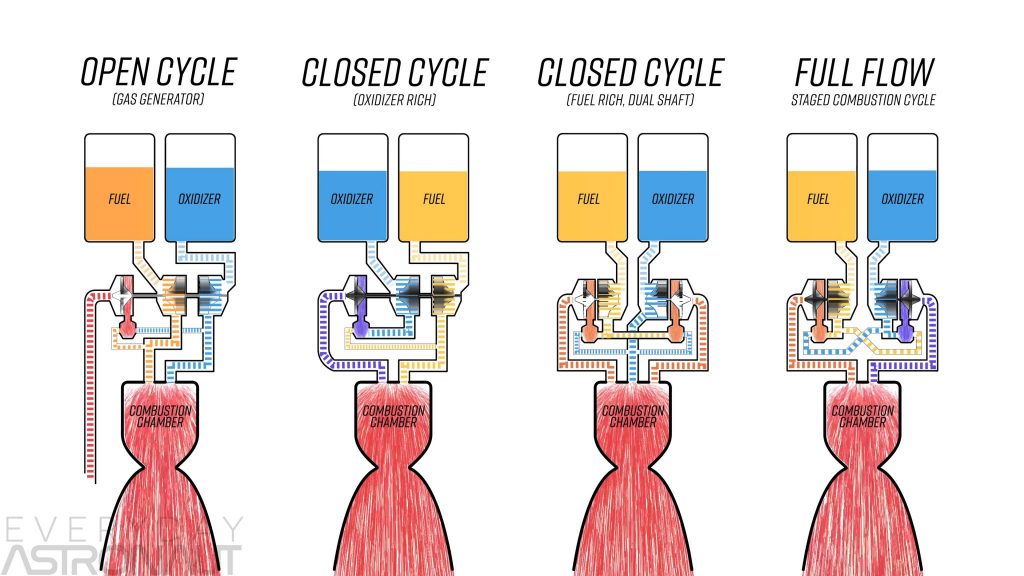

So let’s start with the gas generator cycle otherwise known as the open cycle. This is probably one of the most common types of liquid fueled rocket engines used on orbital rockets. It’s definitely more complicated than a pressure fed system, but it’s fairly simple, well at least compared to their closed cycle counter parts.

Now I’m going to way way over simplify this so it’s as easy to grasp as possible. In real life there’s literally dozens of valves, a hive of wires and extra small pipes, helium to back pressure the tanks, fuel flowing through the nozzle and the combustion chamber to cool it, and an ignition source for the preburner and the combustion chamber….

But again, for the purposes of making this simple and as digestible as possible, just know there’s a lot of stuff missing, but we’re focusing on the flow of these engines to get that concept down. Then once you grasp these simple versions, it’ll be much easier to look at one like this and not have your head explode.

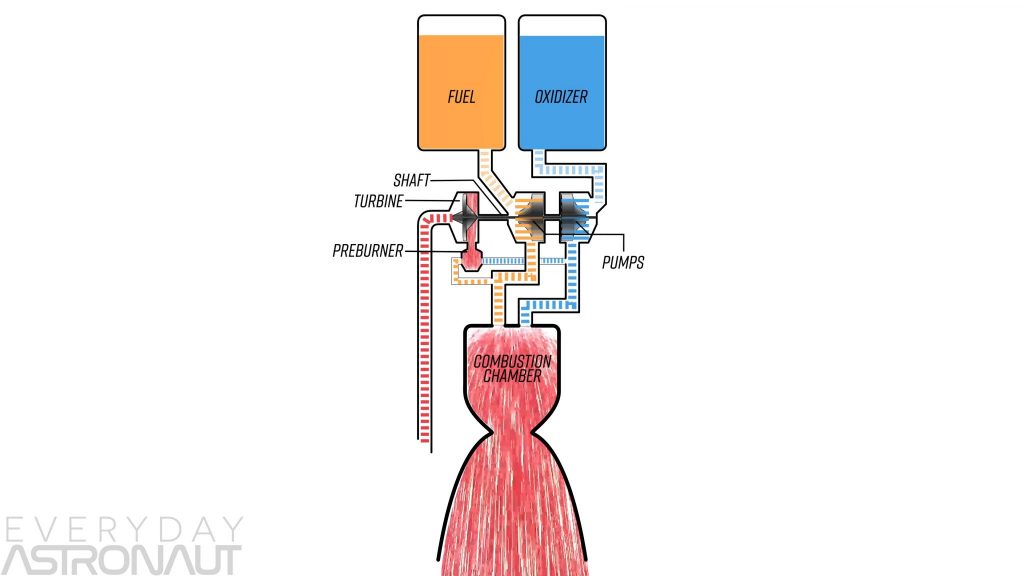

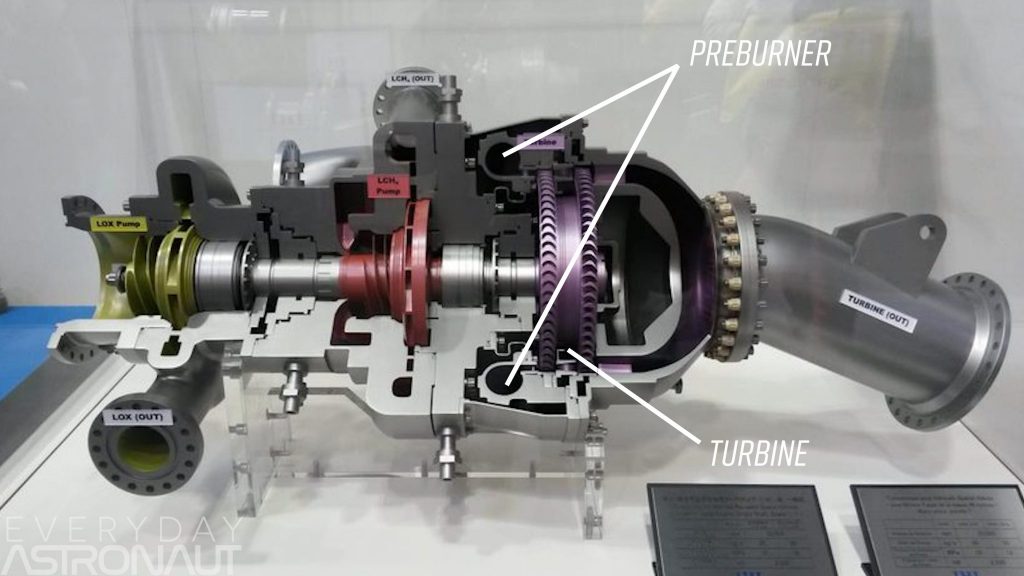

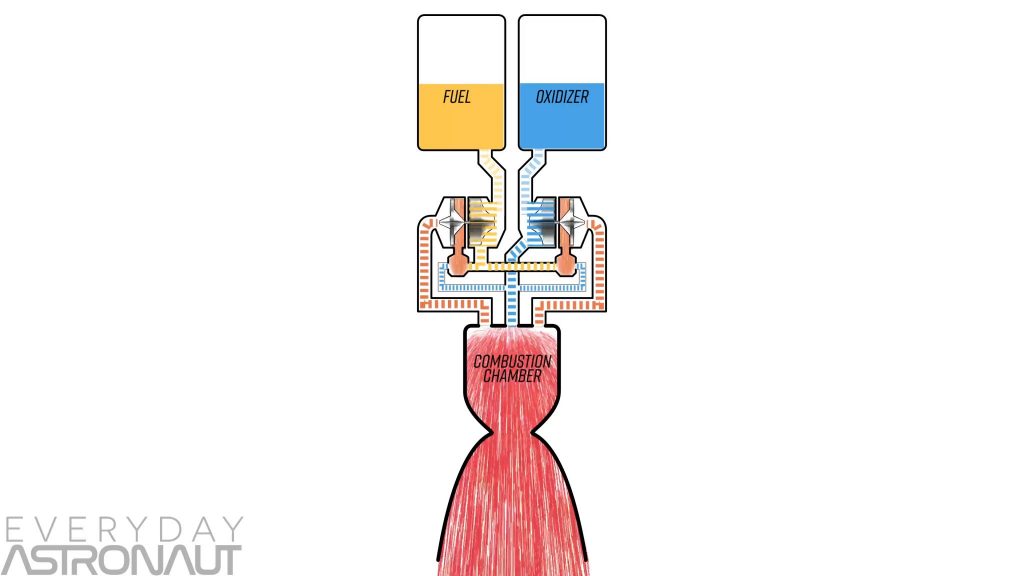

The gas-generator cycle works by pumping the fuel and oxidizer into the combustion chamber using a turbopump. The turbopump has a few main parts, a mini rocket engine called the preburner, a turbine connected to a shaft and then a pump or two that push propellant into the combustion chamber.

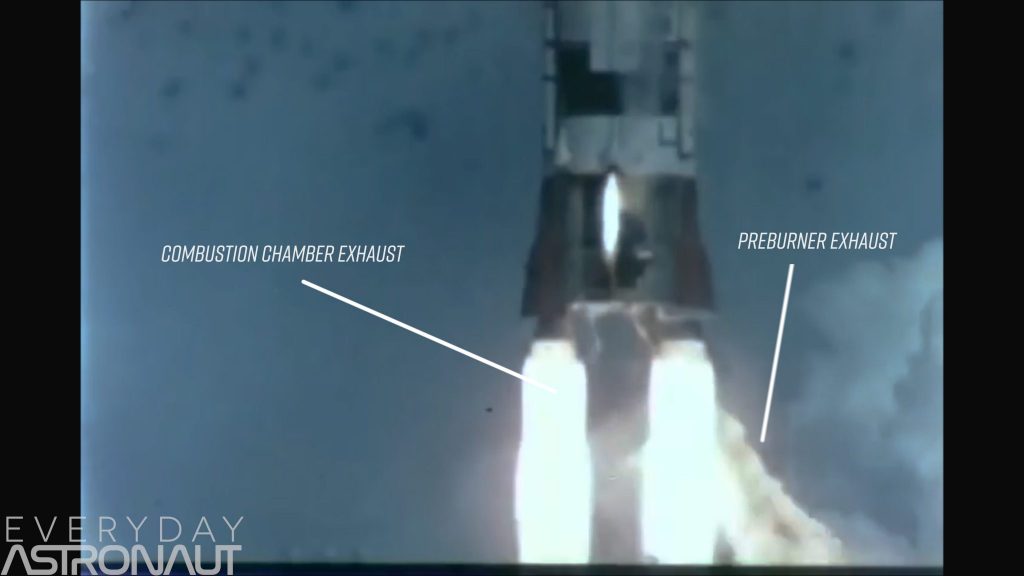

You might hear the turbopump assembly called the powerpack because it really is what powers the engine. In the open cycle system, the spent propellant from the preburner is simply dumped overboard and does not contribute any significant thrust. This makes it less efficient since the fuel and oxidizer used to spin the pumps is basically wasted.

Now the funny thing about a turbopump is that it’s kind of has a chicken and egg syndrome situation that makes it pretty difficult to start up since the preburner that powers the turbopump needs high pressure fuel and oxidizer to operate… So the preburners requires the turbopumps to spin before it can get up to full operational pressure itself, but the turbopumps need the preburner to fire in order to spin the turbopumps… but the preburner needs the turbopumps etc etc

This makes starting a gas generator tricky. There’s a few ways to do this, but we don’t need to get into all of that in this article, that sounds like a fun topic for a future article though.

So back to the turbopumps, remember, pressure always flows from high to low, so the turbopumps need to be a higher pressure than the chamber pressure. This means the inlets leading into the preburner is actually the highest pressure point in the entire rocket engine, everything downstream is lower pressure.

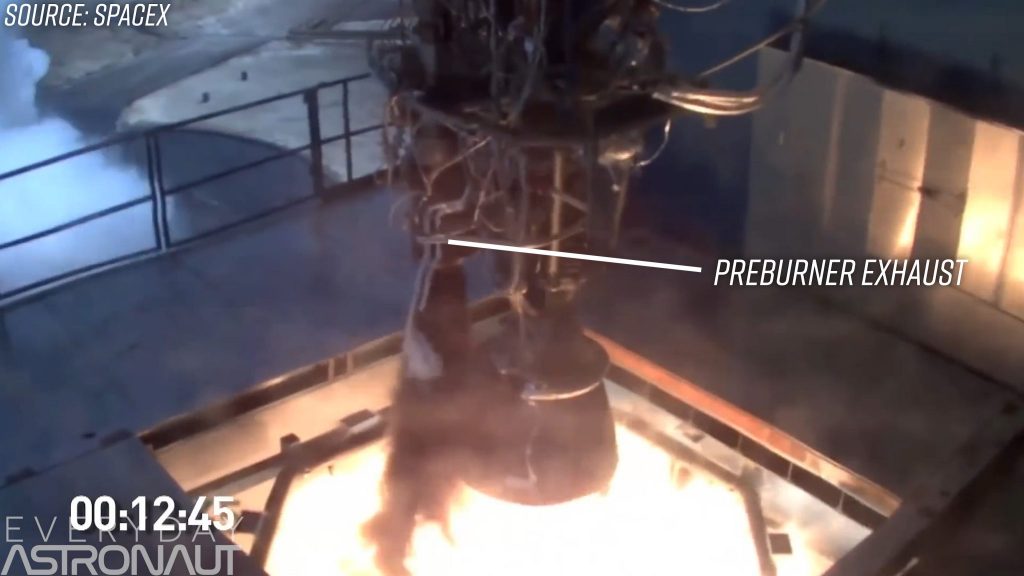

But notice something here. Take a look at SpaceX’s Merlin engine which runs on RP-1 or Rocket Propellant 1 and Liquid Oxygen. Notice how black the smoke is coming out of the preburner exhaust…

Why would it be so sooty compared to the main combustion chamber which leaves almost no visible exhaust? Well that’s because rocket propellant can get super hot…. Like thousands and thousands of degrees Celsius. So to make sure the temperature isn’t so hot it melts the turbine and the entire turbopump assembly, they need to make sure it’s cool enough to continually operate. Running at the perfect fuel and oxygen ratio is the most efficient and releases the most energy, but it also produces a crazy amount of heat.

In order to keep the temperatures low, you can run the preburner at a less than optimal ratio, so either too much fuel known as fuel rich or too much oxidizer or oxygen rich. Running an RP-1 engine fuel rich means you’ll see some unburnt fuel appearing as dark clouds of soot. The highly pressurized unburnt carbon molecules bond and form polymers which is a process known as coking. This soot starts to stick to everything it touches and can block injectors or even do damage to the turbine itself!

So what if you didn’t want to waste that highly pressurized propellant… I mean afterall, since it’s running cooler by being fuel rich, doesn’t that mean there’s a bunch of unburnt fuel literally being wasted? What if you could just pipe that hot exhaust gas and put it into the combustion chamber? Welcome to the closed cycle!

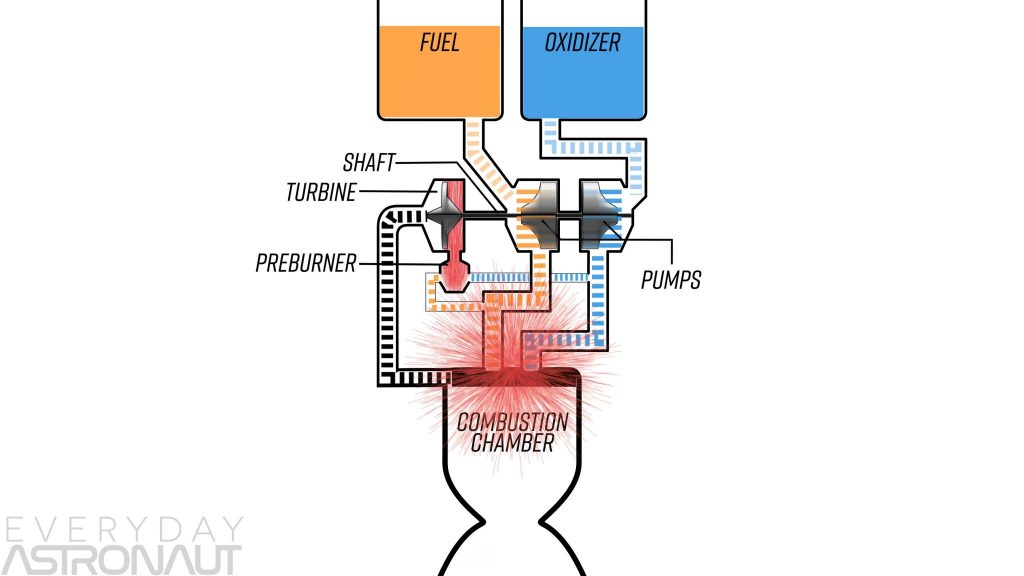

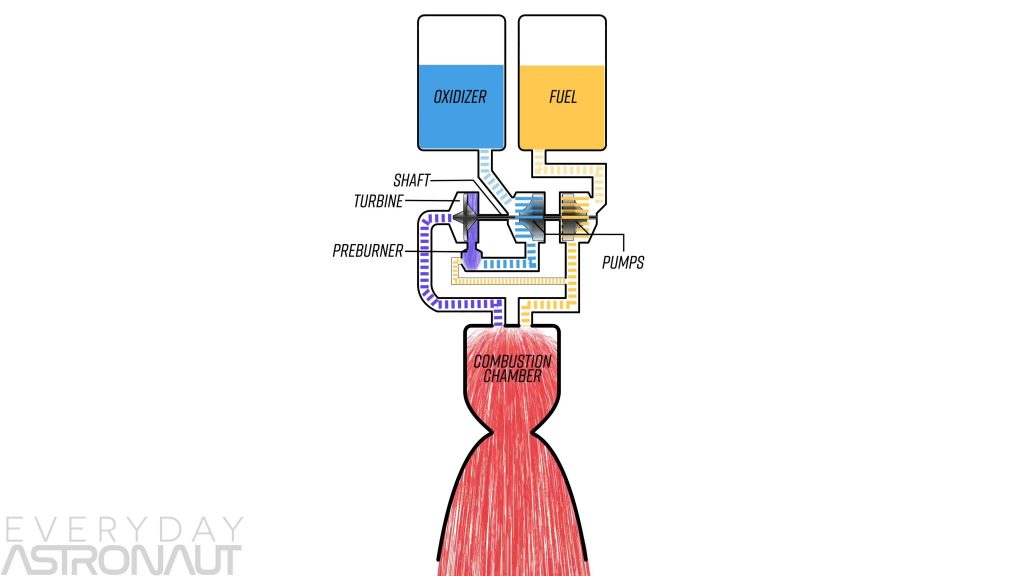

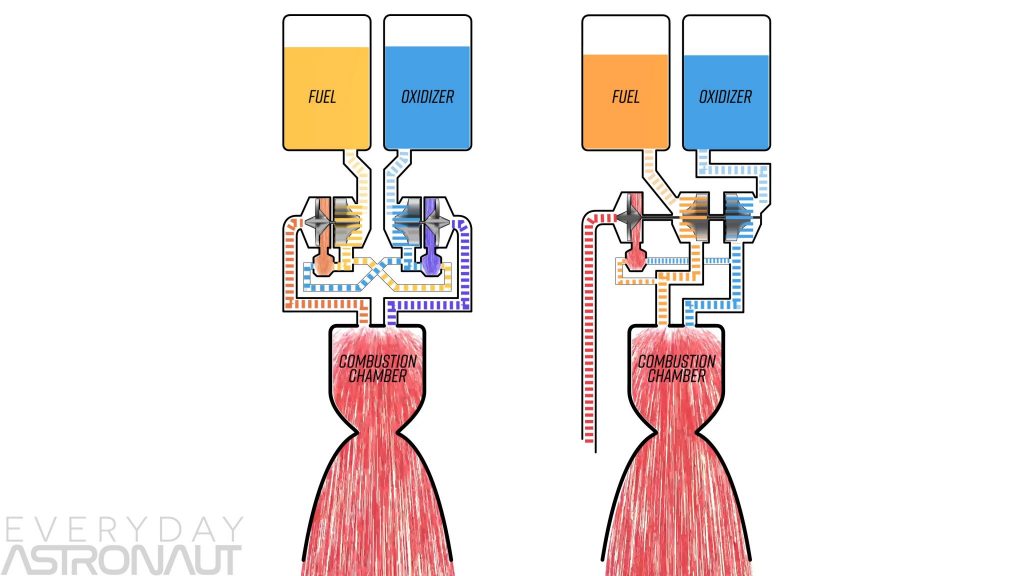

The closed cycle or staged combustion cycle increases engine efficiency by using what would normally be lost exhaust and connects it to the combustion chamber to help increase pressure and therefore increase efficiency.

So let’s take the Merlin engine and try closing the loop. Let’s take that exhaust and just pipe it into the combustion chamber! UH OH!!!! OH NOOOOOOO we just put a bunch of soot and clogged all your injectors. You do not go to space today.

But there’s a few solutions to this problem, so let’s see how the Soviets solved this problem. The first operational closed cycle engine they made was the NK-15 designed for their N-1 moon rocket, they later upgraded it to the NK-33 and then many versions from there stemmed out including the RD-180 which is what is used on the Atlas V today.

Since the NK-15 and NK-33 runs on RP-1 like the Merlin, you can’t run your preburners fuel rich because of the coking problem… so if you want to create a closed cycle engine with RP-1 the answer is running the preburner oxygen rich. Easy as that right? Well now you’re blasting SUPER HEATED highly pressurized gaseous oxygen which will turn anything into soup, right at a precision machined, crazy high tolerance turbine blade.

Doing this was actually considered impossible by the United States, so they basically gave up on trying. They didn’t think a metal alloy existed that could withstand these crazy crazy conditions, and they didn’t believe the Soviets made such an efficient and powerful RP-1 powered engine until after the collapse of the Soviet Union and US engineers got to see them and test them out first hand! But the Soviets had indeed worked their butts off and made a special alloy that can magically, with science, withstand the crazy conditions of an oxygen rich preburner.

With a closed cycle engine, you don’t just use some fuel and some oxidizer and burn that in the preburner to spin the turbine, you actually shoot ALL of the rich propellant through the turbine. So with an oxygen rich cycle, all of the oxygen actually goes through the preburner and just the right amount of fuel goes to the preburner. You only need enough to give the turbine the right amount of energy to spin the pumps fast enough to get the right pressures for the preburner and the combustion chamber to make the right power to shoot a thing into space AH

Sorry, so back to this oxygen rich preburner, that now hot gas oxygen is forced into the combustion chamber where it meets liquid fuel. They meet and go boom and we get a nice clean and efficient burn without really wasting any propellant! HUZZAH!

BUT STILL like all engines, the chamber pressure cannot be higher than the pump pressure, so the pumps actually have a lot of weight on their metal little shoulders.

Now if you’re sitting there wondering if the United States just sat back and let the Soviets have all the closed cycle glory, you’d be wrong. It took the US a bit longer, but they eventually figured out a closed cycle engine, but it was very different from the oxygen rich cycle… The United States pursued a closed loop cycle but they went with a fuel rich preburner. But wait…. We just learned that a fuel rich preburner’s exhaust is so sooty, it will ruin just about anything… right?

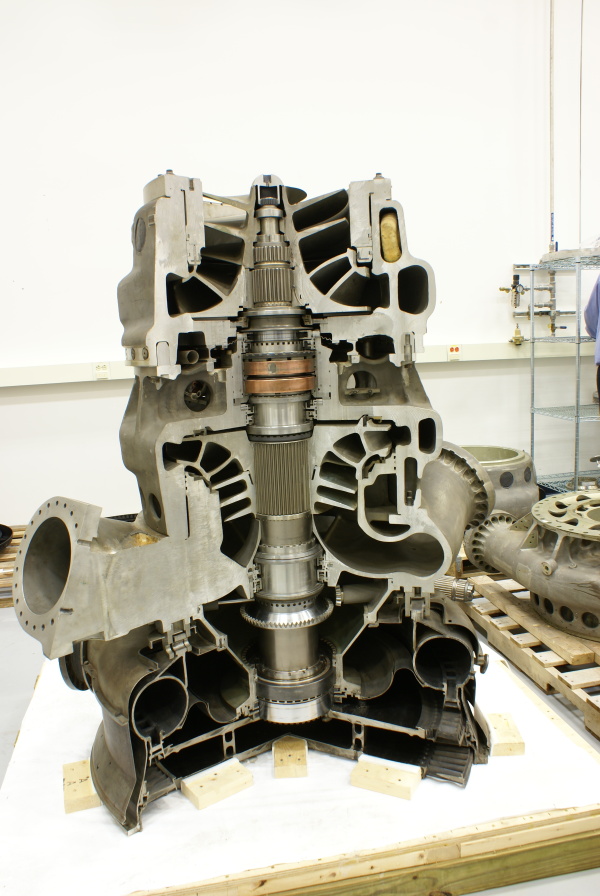

Well sure, if you’re using RP-1 or any other carbon heavy fuel, that’s definitely going to be the outcome… so the United States went with a different fuel, Hydrogen! Ok, so now we’ve avoided one problem of blasting crazy hot high pressure oxygen at everything dear and precious, but now we’ve opened up a new can of worms… Hydrogen is significantly less dense than RP-1 or liquid oxygen. As a matter of fact, it’s so much less dense it takes a HUGE turbopump to flow the right amount of hydrogen into the combustion chamber.

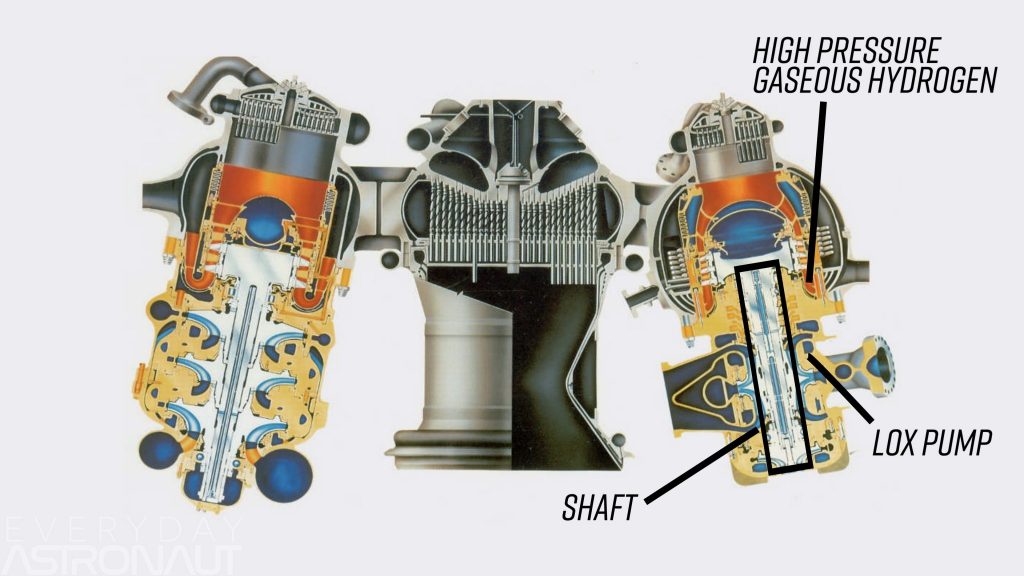

Since RP-1 and LOX are relatively similar density and ratios, they can be run on a single shaft using a single preburner…. But with Hydrogen you need to run even more Hydrogen per mass of oxygen, so between being less dense and needing a higher fuel ratio with Hydrogen, the pumps are drastically different between the Hydrogen and LOX.

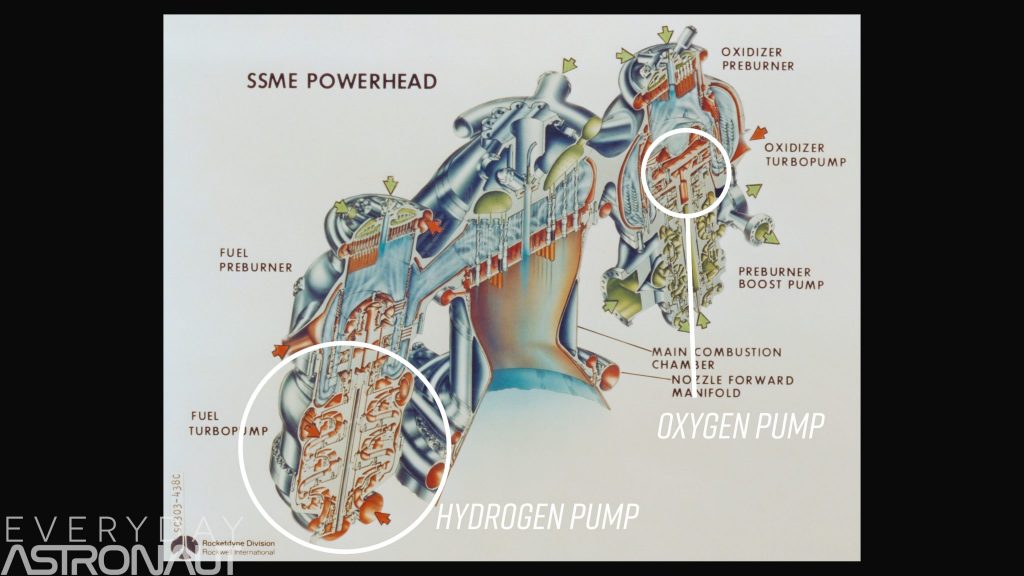

Because of this, the engineers at Rocketdyne pursued an engine known as the RS-25 which would go on to power the space shuttle. They realized that because of the large difference between pumps, they might as well just have two preburners, one for the hydrogen pump and one for the oxygen pump. So that’s what they did!

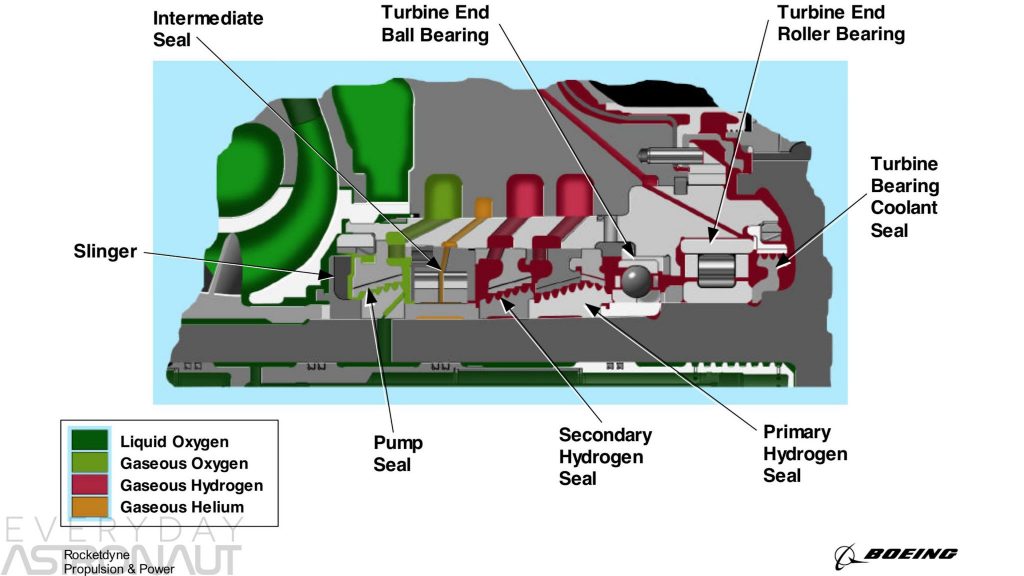

But having two separate shafts created ANOTHER new problem. Now engineers were putting high pressure hot gaseous hydrogen on the same shaft and right next door to the liquid oxygen pump. If some of the hydrogen would leak out of the preburner, it would start a fire in the lox pump, which is catastrophically bad. Hydrogen is also very hard to contain, because it’s so not dense, un dense? Lightweight? It likes to sneak through cracks and get out anywhere it can. So engineers had to make an elaborate seal to keep the hot hydrogen from sneaking out.

The seal required for this is called a purge seal and it’s actually pressurized by helium so it’s the highest point of pressure, so if the seal leaks, it just leaks inert helium! Genius. But take a look at how different the LOX turbopump and the hydrogen turbo pump seals look. You can tell how much more engineering time and effort had to go into those lox seals. THE PEOPLE THAT THINK OF THIS STUFF ARE NUTS!!!!!

Ok now that we’ve talked all about the dual burner, fuel rich RS-25, here’s a simplified diagram of that. I didn’t bother making the fuel pumps different sizes as I just want to focus on the flow here and help make that simple.

But do note, both preburners of the RS-25 BOTH run fuel rich, they just power different pumps. The RS-25 is still considered to be about the best engine ever made with a fairly high thrust to weight ratio and unmatched efficiency.

So the closed cycle improves the overall performance of the engine and is highly advantageous, so how could it get any better than this?

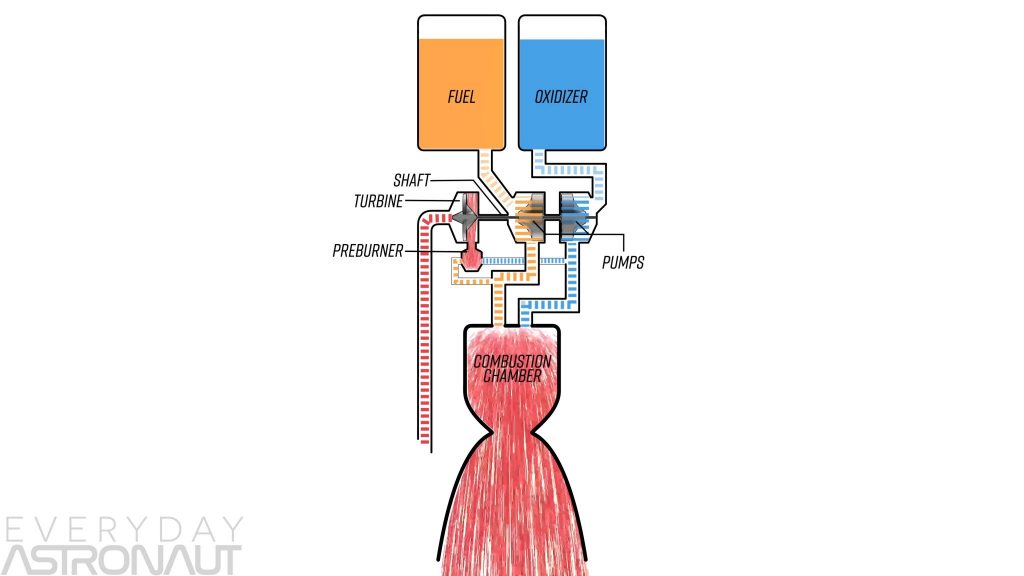

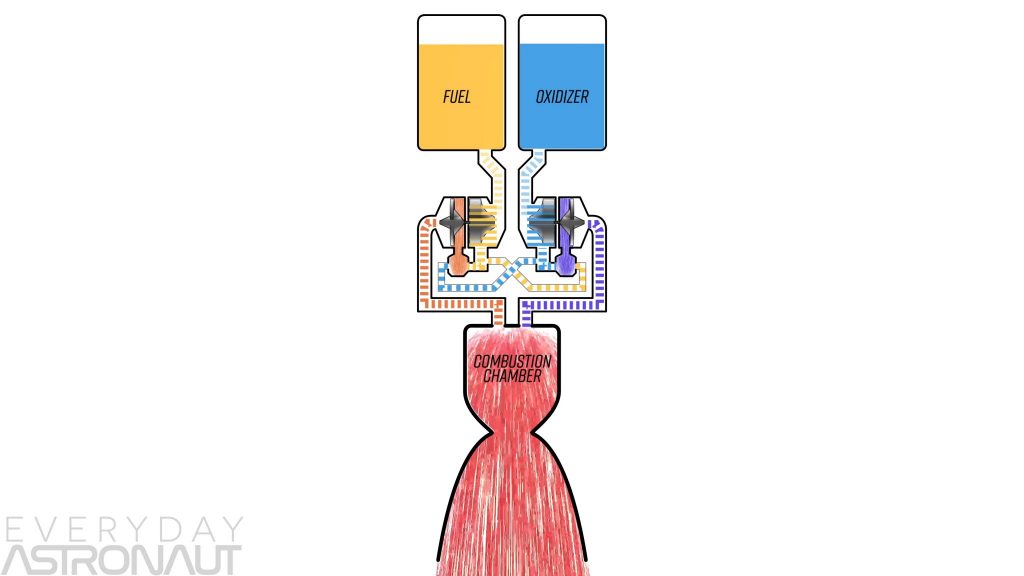

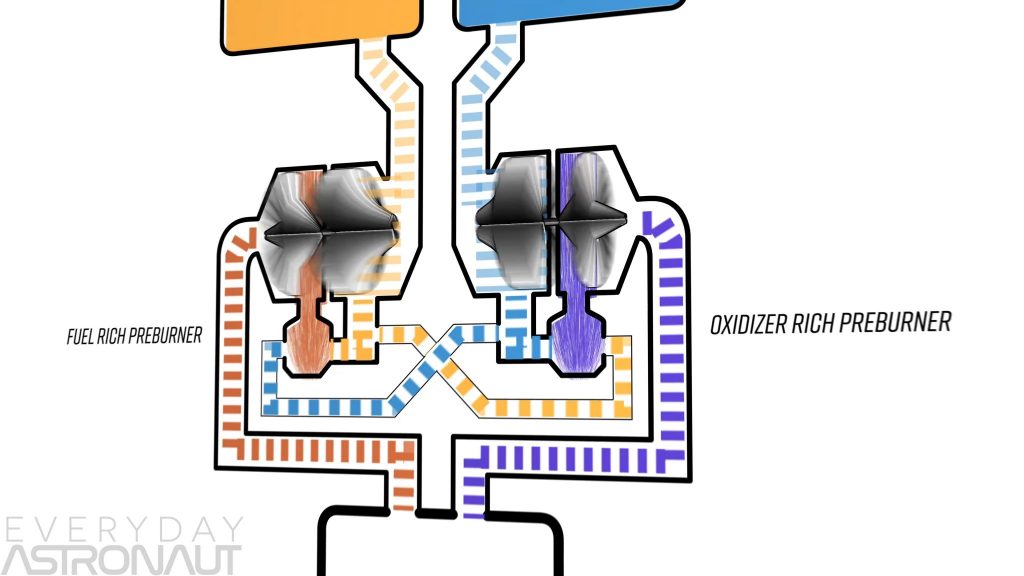

We’re finally ready to talk about the full flow staged combustion cycle which basically just combines the two closed cycle methods we just talked about. With the full flow staged combustion cycle, you take two preburners, one that runs fuel rich and one that runs oxygen rich. The fuel rich preburner powers the fuel pump and the oxygen rich preburner powers the LOX. This means the full flow cycle needs to tackle the oxidizer rich problems, which again is solved by developing very strong metal alloys.

So, SpaceX developed their own superalloy in house that they named SX500. According to Elon, it’s capable of over 800 bar of hot oxygen-rich gas. That may have been one of the biggest hurdles in developing the Raptor engine.

Luckily, the fuel rich side only pumps fuel, so if some hot fuel leaks through the seal on the shaft, it just comes in contact with more fuel, no big deal. Full flow likely wouldn’t work with RP-1 due to the coking problems with a fuel rich preburner, but other fuels are still valid to use this design, more on that in a minute…

The advantage of this system is that since both the fuel and oxidizer arrive in the combustion chamber as a hot gas, there’s better combustion and hotter temperatures can be achieved. There also is less need of that crazy sealing system as we mentioned earlier, which makes for less refurbishment. That’s a good thing when you plan to reuse your engine over and over with little to no maintenance between flights.

And lastly because there’s an inherent increase in mass flow, or how quickly all the propellant is shooting into the preburner, the turbines can run cooler and at lower pressures because the ratio of fuel and oxidizer needed to spin the turbopumps is much lower. And think of it this way, in an open cycle, you only want to use as little fuel and oxidizer as possible in the preburners since it’s all wasted, and you want it to be as hot as withstandable to make it more efficient.

But with a full flow cycle since ALL of the fuel and ALL of the oxidizer goes through the preburners, you can burn as much propellant as necessary to power the turbopumps…. BUT, your fuel to oxidizer ratio will be so crazy fuel rich and oxygen rich that the temperatures at the turbines will be much lower and this means longer lifespans for the turbopump assembly. It also means more combustion happens in the combustion chamber and less in the preburner.

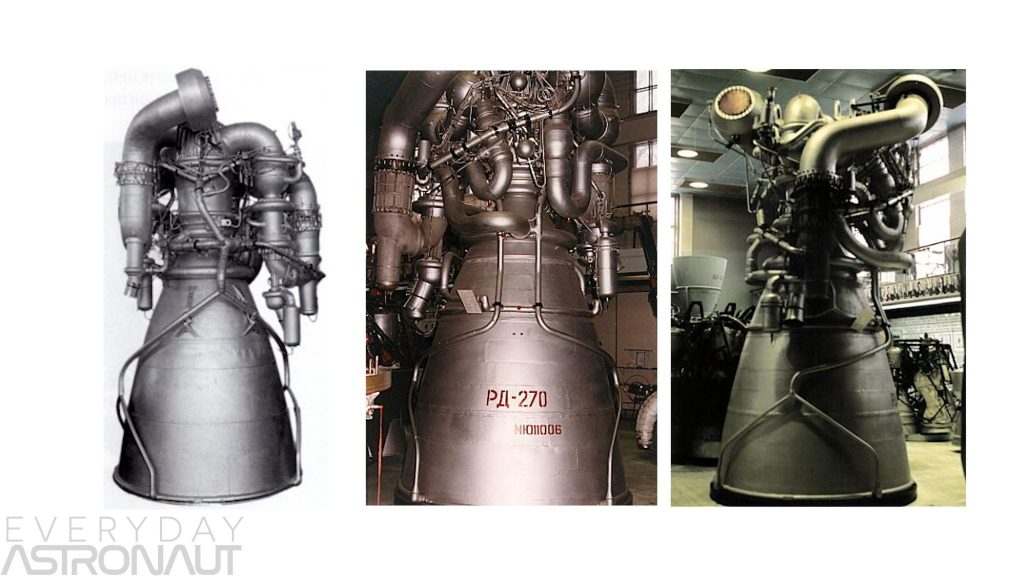

Now here’s the crazy part. Only three engines have demonstrated the full flow staged combustion cycle… EVER.

In the 60’s the Soviet’s developed an engine called the RD-270 which never flew, and in the early 2000’s Aerojet and Rocketdyne worked on an integrated powerhead demonstrator called, wait for it, the integrated powerhead demonstrator which again, never made it past the test stand.

And the third attempt at developing a full flow staged combustion cycle engine is SpaceX’s Raptor engine!!!! TA DA!!! WE DID IT!!!

That’s right, the Raptor engine is only the THIRD attempt at making this crazy type of engine. It’s the first to ever do any work and leave the test stand! And fingers crossed, it’ll be the first full flow staged combustion cycle engine to reach orbit too. Well, actually, just about everything this engine does will be a first.

But all this means SpaceX had to tackle many very difficult problems. Not only did they need to solve the same problems with an oxygen rich cycle, they also had to precisely control fuel to create the highest chamber pressure of any rocket engine ever, at 270 bar, finally beating the RD-180’s record of around 265 bar. And they’re not done, they’re targeting 300 bar, which is just plain nutty, more on that in a second.

Since the Raptor can’t run a fuel rich preburner using RP-1, you’d think the next most logical choice would be Hydrogen… well SpaceX didn’t opt for either RP-1 or Hydrogen, they went with Liquid Methane! So NOW we finally have another topic to touch on… why did SpaceX chose liquid methane for the Raptor engine? What are the qualities that make it advantageous over hydrogen or RP-1?

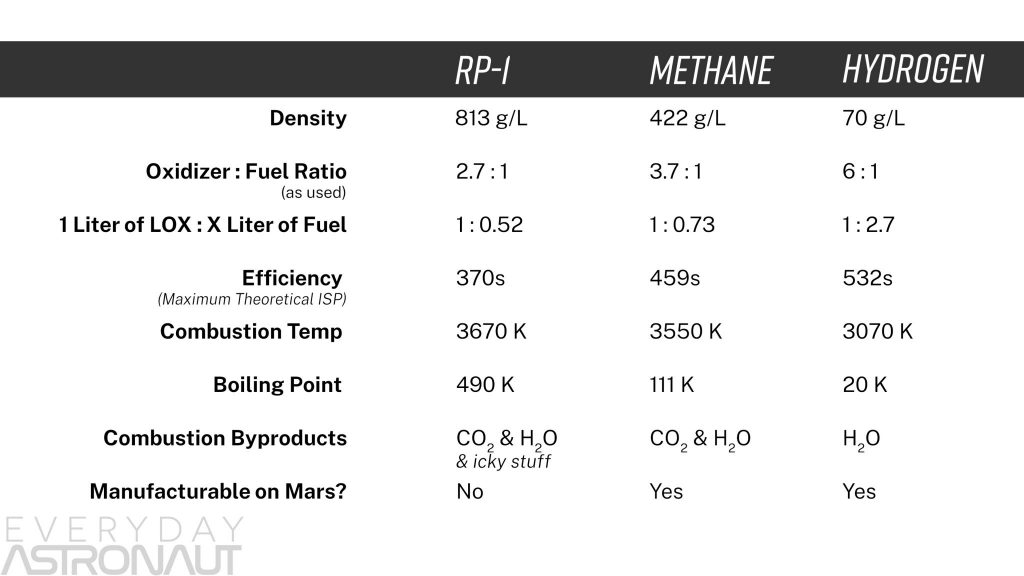

To date, no liquid methane or methalox engine has gone to orbit, so what qualities does it have that make it desirable? Let’s take a look at methalox compared to keralox and hydrolox… let’s put methane in between RP-1 and Hydrogen… you’ll see why pretty quickly…

So let’s start off with perhaps the biggest factor when designing your first stage. The density of the propellant. Having a denser fuel means the tanks are smaller and lighter for a given mass of fuel. A smaller tank = a lighter rocket.

So here’s the density of these three fuels measured in grams per liter, in other words how much does one liter of this stuff weigh, or really what’s its mass?

Starting off with RP-1, one liter is around 813 grams, RP-1 is 11 times more dense than Hydrogen which is only 70 grams per liter, and Methalox is right in the middle at 422 grams per liter.

Remember how airships or zeppelins used to be filled with hydrogen to make them “lighter than air”… That’s because Hydrogen is so much less dense than our atmosphere, it makes for an excellent, albeit flammable gas for a balloon. I mean, we all remember the Hindenburg… right?

It should also be noted that 813 grams per liter is an average for RP-1, but SpaceX chills their RP-1 in their Falcon 9 and Falcon Heavy for about a 2%-4% increase in density. But historically, RP-1’s density is right around that 813 grams per liter.

So in the case of density, Methane is kind of right in the middle of the others. But there’s more to it than just density, we also need to take into consideration the ratio of how much fuel is burned compared to how much oxidizer is burned. This is the oxidizer to fuel ratio.

So here’s where things get a little more interesting and the tables turn a little. Rocket engineers have to take into account the mass of the fuel and the corresponding weight of the tanks, so they don’t actually burn propellant at the perfect stoichiometric combustion ratio, they find the perfect happy medium that balances tank size with thrust output and specific impulse.

Let’s look at the mass ratios of fuel and oxidizer that the engineers have come up with… So for these numbers RP-1 is burned at 2.7 grams of oxygen to 1 gram of RP-1, Hydrogen burns at 6 grams of oxygen to 1 grams of hydrogen, and Methane burns at 3.7 grams oxygen to 1 grams Methane. These numbers can now help offset a little the massive difference in density.

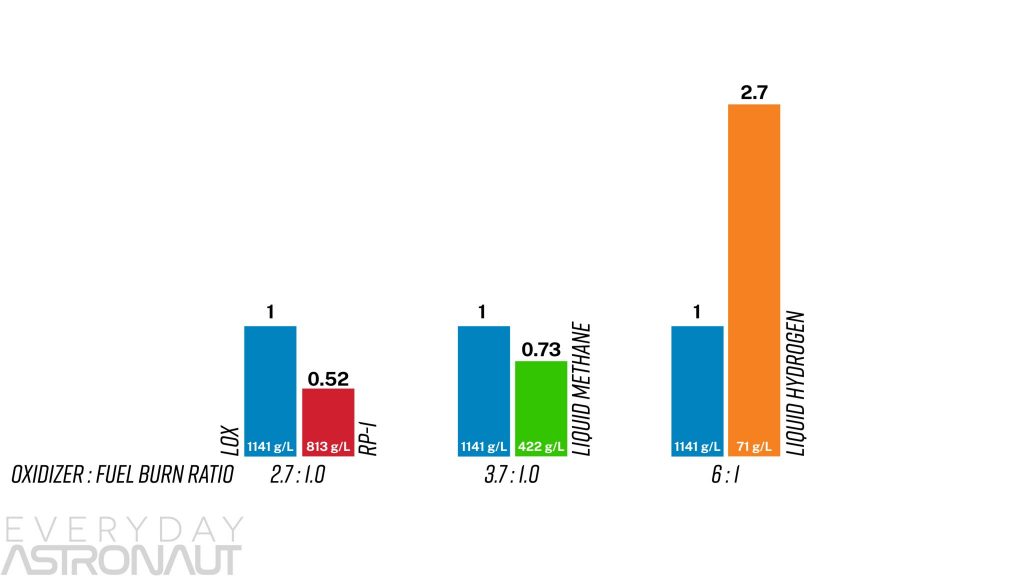

So let’s visualize this to help make it easier to digest. Liquid oxygen is 1,141 grams per liter, it’s a little more dense than RP-1. So burning LOX and RP-1 at a 2.7 to 1 ratio, for every liter of LOX you’d need a little over half a liter of RP-1. Next up let’s do Hydrogen. Now with Hydrogen being 11 times less dense than RP-1, you’d think it’d need a tank that’s 11 times bigger… but luckily, engineers have found that it pays to burn LOX and Hydrogen at a 6:1 ratio for a good compromise.

This means for each liter of LOX, you’d need 2.7 liters of hydrogen! So your fuel tank needs to be approximately 5 times larger compared to RP-1… so yeah…

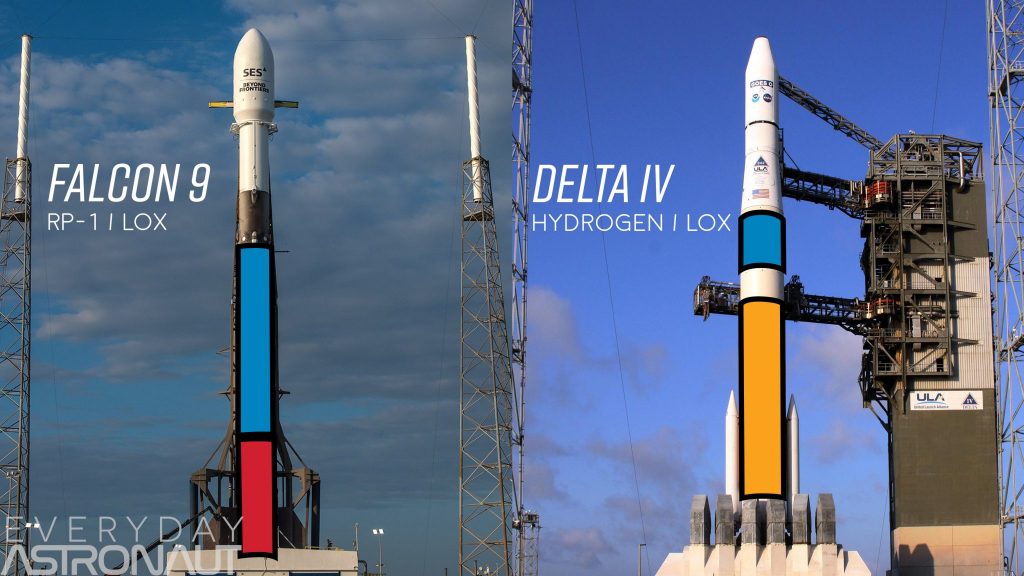

That’s why when we look at a Hydrogen powered Delta IV vs an RP-1 powered Falcon 9, you can see the fuel tank is much smaller than the LOX tank on the Falcon 9, but the Delta IV is about the opposite! The LOX tank is MUCH smaller than it’s fuel tank.

So now let’s look at that methane. Now this one is interesting. LOX is 2.7 times more dense than liquid methane, but the burn ratio is 3.7 grams of oxygen to 1 gram of methane. So you’d need .73 liters of methane for every liter of LOX. In other words, your fuel tank would need to be about 40% bigger for methalox than it would need to be for RP-1, despite RP-1 actually being almost twice as dense! And compared to Hydrogen, it’s fuel tank would be 3.7 times smaller.

So the fuel to oxidizer ratio helps make Methalox’s fuel tanks a lot closer to RP-1 than it is to Hydrolox.

Another huge variable with any rocket engine is how efficient it is. This is measured in specific impulse or ISP, but you can think of this like the fuel economy of a gas powered car. So a high specific impulse would be similar to a high mpg or kmpl. The best way to think of specific impulse is imagine you had one kg of propellant, for how many seconds can the engine push with 9.81 newtons of force? The longer it can sip on the fuel while still pushing that hard, the higher its specific impulse, and therefore the more work it can do with the same amount of fuel. IE, it’s fuel economy.

So the higher the specific impulse, the less fuel it takes to do the same amount of work, which is a good thing. A fuel efficient engine is extremely important! And now due to the molecular weight of each fuel and their energy released when burned, there’s a different potential for how quickly the exhaust gas can be expelled out the nozzle. This means each fuel has a different theoretical specific impulse.

In an ideal and perfect world an RP-1 powered engine could achieve about 370 seconds, an ideal Hydrogen powered engine could get 532 seconds and guess what, a methane powered engine is right in the middle with 459 seconds. Real world examples of this though are much lower with RP-1 engines seeing around 350 seconds (Merlin 1D Vacuum), around 380 seconds for a methane engine (raptor vacuum) and about 465 seconds for a hydrogen engine (RL-10B-2)

Next, let’s talk about how hot each fuel burns. A fuel that burns cooler is easier on the engine and potentially makes for a longer lifespan. RP1 can burn up to 3670 kelvin, Hydrogen 3,070 kelvin and if you haven’t guessed it by now, Methane is again between the two at 3550 kelvin.

Speaking of thermal considerations, let’s look at the boiling point of these fuels or at what point does the liquid fuel boil off and turn into a gas? Since all of these fuels need to remain in their liquid state in order to stay dense, the higher the temperature, the easier it is to store the fuel. A higher boiling also means less or even no insulation on the tanks to keep the propellant from boiling off. And of course, less insulation means lighter tanks. YAY.

RP-1 has a very high boiling point, even higher than water at 490 kelvin. Hydrogen on the other hand is near absolute zero at a crazy crazy cold 20 kelvin! That is insanely cold and it takes serious considerations to keep anything at that temperature. And like the goldilocks it is… methane is between the two at 111 kelvin, which although that’s still very cold, and requires thermal considerations, it at least boils off at a temperature similar to LOX, so there’s that!

And because it’s so close to the temperature of LOX, the tanks can share a common dome, which makes the vehicle lighter. LOX and Hydrogen’s temperatures vary so wildly that LOX will boil off hydrogen and the hydrogen will freeze the LOX solid!

Now onto exhaust, what are the byproducts of combustion with these engines? RP-1 is really the only one of these three that really pollutes with any unburnt carbon being left in the atmosphere along side water vapor, but Hydrogen only produces water vapor and Methane produces some carbon dioxide and water vapor. But an interesting note, believe it or not, as far as greenhouse gases go, water in the upper atmosphere can be pretty bad… But, I’ll be doing an article in the future about how much rockets pollute, talking about both air pollution, but also ocean pollution and even space debris as a consideration. So standby as that’s one that I think is very interesting!

One metric we’re going to talk about, but only generally is the cost associated with each fuel. These tend to vary considerably and it’s actually really hard to pin down exact prices reliably. But for considerations, RP-1 is basically a highly refined jet fuel, which jet fuel is a highly refined kerosene, which kerosene is a highly refined diesel. So, it’s safe to assume it’s going to be more expensive than diesel fuel.

Hydrogen is also relatively expensive despite being abundant, refining it, storing it and transporting it can be expensive. Methane on the other hand is basically the same thing as natural gas and can be relatively cheap. When you’re talking about buying literal tons of fuel, the fuel cost can add up quickly, so although the cost of fuel shouldn’t factor in too much, it certainly is a consideration… but without hard data on this one, I don’t even want to put it on our chart, SO, instead… let’s talk about the more important aspect of the fuel. Manufacturing it…

Here’s where we get into specifically why SpaceX sees Methane as an important, or even a necessary part of their companies future.

SpaceX’s ultimate goals are to develop a system capable of taking humans out to Mars and back over and over. The Mars atmosphere is CO2 rich, combine that with water mining from the surface and subsurface water on Mars through electrolysis and the sabatier process, the Martian atmosphere can be made into Methane fuel! So you don’t have to take all the fuel you need to get home with you. You can make it right there using Mars’ resources.

This is called in-situ resource utilization or ISRU. Now you might be thinking, well if there’s water, can’t you just make Hydrogen on the surface of Mars for your fuel? Well, yes, but one of the biggest problems with Hydrogen and long duration missions is the boiling point of Hydrogen. It takes serious considerations to maintain Hydrogen in a liquid state necessary to be a useful fuel.

So for SpaceX, methane makes a lot of sense! It’s fairly dense meaning the rockets size remains reasonable, it’s fairly efficient, it burns clean and makes for a highly reusable engine, it burns relatively cool helping expand the lifespan of an engine, which again is good for reusability, it’s cheap and easy to produce and can be easily produced on the surface of Mars!

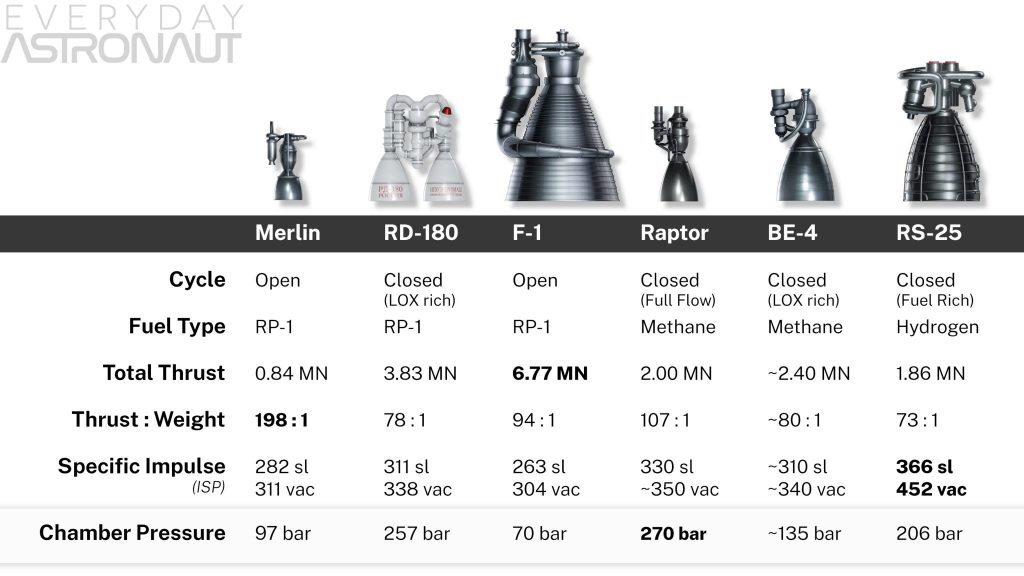

Ok yay! We’ve made it this far! Now that we have a strong grasp of how different engines operate and the fuels they might use, we can finally line them all up side by side and compare their metrics to help appreciate where each engine sits..

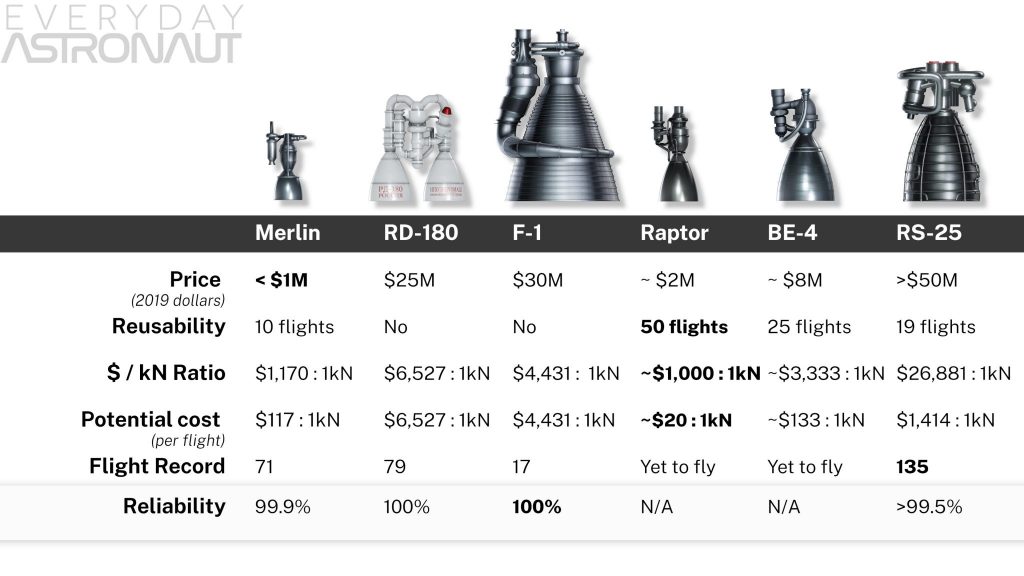

So now we’re going to line up engines by their fuel types and cycles. So let’s compare SpaceX’s open cycle Merlin engine that powers their Falcon 9 and Falcon Heavy rockets, NPO Energomesh’s oxygen-rich closed cycle RD-180 that we see power the Atlas V rocket and Rocketdyne’s open cycle F-1 engine that powered the Saturn V which all run on RP-1. Then we have SpaceX’s full flow staged combustion cycle Raptor engine that will power their Starship and Super Heavy booster and Blue Origin’s closed cycle oxygen rich methane powered BE-4 engine that will power their New Glenn rocket and ULA’s upcoming Vulcan rocket, and Aerojet Rocketdyne’s closed cycle fuel rich RS-25 engine that powered the space shuttle and will power the upcoming SLS rocket which runs on Hydrogen.

A few quick notes here. The Raptor and BE-4 as of the making of this article are still in development, so the numbers we have are either in their current state of progress like the Raptor which is constantly improving and in the case of the BE-4, those are the target goals for the engine which Blue Origin has yet to hit. So just keep these numbers in mind that they’re subject to change.

Another fun note… look at the RD-180… now don’t be confused, this is a single engine, it just has two combustion chambers! There’s only a single turbo pump that splits its power to two combustion chambers. The Soviet Union was able to solve the crazy hot oxygen rich closed cycle problem, but they were unable to solve combustion instability of large engines, so instead of one large combustion chamber, they made multiple small ones!

So first up, let’s take a look at their total thrust output at sea level since all these engines run at sea level, that’s a fair place to compare them. Let’s go from the least amount of thrust to the most, for fun 😉 The Merlin produces .84 MNs of thrust, the RS-25 produces 1.86 MNs, the Raptor currently is at 2 MNs, the BE-4 is hoping to hit 2.4 MNs, the RD-180 // 3.83 MNs ad the F-1 is still the king out of these at 6.77 MNs.

The RD-170 actually produced more thrust than the F-1, but since it barely ever flew, I figured it wasn’t as relevant in this line up, figured it’s better to go with engines that have actually been used, a lot!

Thrust is great, but what’s maybe just as important when designing a rocket is the thrust to weight ratio… or how heavy the engine is compared to how much thrust it produces. A higher thrust to weight engine ultimately means less dead weight the rocket needs to lug around.

Let’s start from lowest to highest here. The lowest is actually the Space Shuttle’s RS-25 at 73:1, then there’s the RD-180 which is 78:1, then we have the BE-4 at around 80:1 but keep in mind, we don’t actually have a really good number on this, so there might be some wiggle room there, then the F-1 is 94:1, then we have the Raptor at 107:1 (for now), and lastly the Merlin is actually the leader here with an astonishing 198:1 thrust to weight ratio…. Yeah… that thing is a power house.

Thrust is great and all, but who cares how powerful an engine is if it’s terribly inefficient? So next up let’s check out their specific impulses, which is measured in seconds. For this we’ll show both the sea level specific impulse as well as the specific impulse in a vacuum. So starting with the least efficient engine which is the F-1 engine at 263 to 304 seconds, then the Merlin engine at 282 to 311 seconds, then we get the RD-180 at 311 to 338 seconds and somewhere in that same ballpark is the BE-4 which is AROUND 310 to 340 seconds, next up is the Raptor engine which is 330 to around 350 seconds, and lastly the king here by far is the RS-25 which is 366 to 452 seconds! WOAH.

Now one of the factors that affect both thrust and specific impulse is chamber pressure. Generally, the higher the chamber pressure, the more thrust and potentially more efficiency the engine can gain. Higher chamber pressures let an engine be smaller for a given thrust level, also improving their thrust to weight ratio. The baby here is actually the F-1 which only had 70 bar in its chamber pressure. Now I do need to pause for a second and remind you 70 bar is 70 TIMES the atmospheric pressure… or the same amount of pressure you’d experience at 700 meters underwater… yikes… ok, so even the lowest chamber pressure is still mind boggling high.

So next up is the Merlin engine at 97 bar, then the BE-4 will be around 135 ish, then the RS-25 which is 206 bar, then the RD-180 which has been considered the king of operational engines at 257 bar, that is until the Raptor is now online which is the new king of chamber pressure at a whopping 270 bars currently and they hope to get it up to 300 bar!!! 300 bar is like being 3 km deep in the ocean. I can’t even fathom.

Ok, that’s enough of the specs of these engines, now lets look at their operational considerations. Starting with their approximate cost. Now, again, this can be kind of hard to nail down, so these are the best estimates I could come up with. These numbers do factor in inflation to make them all in today’s dollars.

Let’s go with the most expensive and work our way down to the least expensive. The most expensive engine in this lineup is the RS-25 which has a sticker price of over $50 million per engine… yikes. Then we’ve got the F-1 engine which was $30 million per engine, then the RD-180 which is $25 million per engine, then the BE-4 which is around $8 million per engine, then we have the Merlin engine which is less than $1 million and for the Raptor, Elon has mentioned he thinks they can produce the Raptor for cheaper than or close to the Merlin engine if they can remove a lot of the complexity of the current versions… so for now, we’ll say around $2 million as a pretty decent ball park.

Well, cost is one thing, but another strong consideration for the cost of the engine is whether or not it’s reusable. And here only the RD-180 and the F-1 were not reusable, or at least never reused… which is different than all of these other engines which will all be reused multiple times.

The RS-25 was reused over and over with the record being 19 flights out of a single engine, well after a few months of refurbishment… The Merlin is hoping to see up to 10 flights without major refurbishment. We know a design goal for the BE-4 is to be reused up to 25 times, and I think the Raptor hopes to see up to 50 flights, BUT, again, aspirations are one thing, we’ll see how history treats these claims.

On the topic of price, there’s actually some things that get really interesting when we start looking at these numbers. The first is a number Elon mentioned one interesting metric in a tweet in February of 2019 saying they hope to make the Raptor get better at their thrust to $ ratio.

Now this is a really interesting concept when you think about it. Who cares how much an engine costs if one big engine is cheaper than 2 smaller ones for the same thrust or vise versa. So let’s actually take a look at the $ to kN ratio of these engines. Starting with the most expensive $ to kN engine which is the RS-25 at a crazy $26,881 : kN of thrust, then the RD-180 at $6,527 : 1 kN, followed by the F-1 at $4,431 : 1 kN, and then we get to the BE-4 which is $3,333 : 1 kN, and then the Merlin at $1,170 and the Raptor at around $1,000 : kN.

BUT NOW we can go even another step further since we know their $ / kN ratio but we also know their reusability potential… Now we can predict their potential cost per kN per flight, which changes based on how reusable the engines are.

So for starters, since the RD-180 and the F-1 aren’t reusable, their price stays the same, but for the rest of the engines, if we take into account how many flights they have/will have, now we start to see the RS-25’s reusability pay off and close the gap, bringing it’s potential cost down to just $1,414 : kN, but here’s where things get crazy. Blue Origin’s BE-4 has potential to be truly game changing at around $133 : kN over 25 flights, which could make it about as cheap to operate than the Merlin at $117 per kN per flight. But if the Raptor engine truly lives up to its hype, it could bring that number all the way down to $20 per kN per flight. Now that is absolutely game changing.

Sure, money and reusability is a 21st century focus for spaceflight, but whatever happened to good old proven reliability? For this, let’s first look at how many operational flights each engine has had. At the moment of writing this, the Raptor and BE-4 haven’t seen any operational flights, although the Raptor is starting to leave the test stand and being used on test vehicles like the StarHopper. But for now neither engine has a real flight record. Then we have the F-1 engine which was used on 17 flights, next up the Merlin engine which is at 71 flights and catching up quickly to the RD-180 which is at 79 flights, but the king out of these engines is the RS-25 which saw 135 flights.

Now lastly, how about reliability in service. Between the number of flights and this number, we can get a pretty good sense of how truly reliable an engine is. This number is really hard to just pin down since some engines may have shut down early but the mission was still successful on a few of these examples… so take these with a little grain of salt again. Again, the BE-4 and Raptor haven’t flown yet, so those numbers are unavailable, then we have the Space Shuttle main engine which is over 99.5% reliable, but that gets hard to define when an engine doesn’t fully shut down…

and then we have the Merlin at 99.9% reliable… it helps when you have 10 engines on each flight of the vehicle, and with only one engine ever failing in flight early on in its career, and despite that, the mission was still a success… so it’s a very reliable engine! Now to end this, technically the RD-180 and the F-1 are 100% reliable, but with the F-1 never having any shut down at all in flight, it gets the bold here… and depending on how you define success and reliability, technically, the RD-180 is only kind of 100% reliable, because it got really really lucky once.

One time it shut down 6 seconds early, on an Atlas V mission in 2016, due to a faulty valve, but the mission went on to be a success because of some pure luck with the centaur upperstage having enough spare Delta V to carry out the mission! Had that valve failed even a second earlier and that mission would have failed.

Man… seeing all of these numbers and considerations it makes you realize just how many variables go into designing a rocket. It’s so crazy to think about how if you tweak one little variable how many things that can affect. Change any one thing and it can have a massive ripple effect in the design and implementation of the vehicle as a whole.

So let’s go back over all of this now that we know the cycles, the fuels and the aspirations of SpaceX to see if we can figure out why the Raptor engines exists and figure out if it’s worth all the effort.

Let’s look at SpaceX’s ultimate plan. Make a rapidly and fully reusable vehicle capable of sending humans to the Moon and Mars as inexpensively and routinely as possible. Not your everyday design goal for a rocket huh? In order to be rapidly and fully reusable, the engine needs to run clean and require low maintenance with simple turbopump seals and low preburner temperatures. Hmm, a Methane fueled full flow staged combustion cycle engine sounds like a good fit….

For reliability, redundancy and scale of manufacturing considerations, it makes sense to employ a lot of engines. In order to scale an engine down but maintain a high output, chamber pressure needs to be high… Hmm sounds like a methane fueled full flow staged combustion cycle engine sounds like a good fit…

For interplanetary trips, methane makes the most sense because it’s boiling point makes it usable on long duration trips to say Mars, which guess what, you can produce Methane on Mars… so for interplanetary trips, a methane fueled full flow staged combustion cycle engine sounds like a good fit…

Methane is fairly dense, meaning the tank size remains reasonable. Which again is good for interplanetary trips, not needing to lug around dead weight… making a methane fueled full flow staged combustion cycle engine sounds like a good fit…

So… let’s bring it alllll back around now, is the Raptor engine really the king of rocket engines? Well, rocket science, like all things is a complex series of compromises. Is it the most efficient engine, no. Is it the most powerful engine, no. Is it the cheapest engine, probably not. Is it the most reusable engine, maybe. But does it do everything really well? YES. It truly is a goldilocks engine, doing everything it needs to do very very well. It is the perfect fit for your interplanetary spaceship.

And despite its complexity, SpaceX is developing this engine at a rapid pace. Knowing how much tweaking SpaceX did to their Merlin engine over a decade, we’re just at the infancy of the Raptor engine. It will only get better and better from here on out, which is crazy!

So all in all, the Raptor engine IS the king of THIS application. It’s a fantastic engine to fufill SpaceX’s goals for their Starship vehicle. Would it be the king of other applications? Maybe, maybe not, and I’ll leave that decision for the rocket scientists and engineers who get to make all of those crazy compromises!

So what do you think? Is it worth all the hassle to develop such a crazy and complex engine? Is this just the beginning for the Raptor engine? And most importantly, is the Raptor engine really the king of rocket engines? Let me know your thoughts in the comments below.

If you want to help me continue to do what I do, please consider supporting by becoming a Patreon member! Patreon members gain access to our exclusive subreddit, an exclusive discord channel, they get bonus material AND exclusive livestreams!

F-1 Turbopump photo provided by Mike Jetzer/heroicrelics.org

How do you know Raptor t/w is 107? I have never seen that figure published before…

Einstein said you can say anything using only one side of a piece of paper. Really too bad you went far, far against his advice.

Reality can be whatever I want

Come on! Aren´t you being too harsh on Tim?…

Sure, you can say any ONE thing using only one side of a piece of paper. But if you want to say MANY things, you need lots of paper. Obviously.

OK, I know it is a crazy, crazy world in June, 2020 – probably even more reason to make sure we have good, strong, reliable, economical, efficient – LONG JOURNEY rocket engines – to get off this damn planet!

So where is the 1YR update on the SpaceX/Blue Origins rockets??

Time for a journey through The System!

To Mars and beyond!

©®™✓£¢€… x°[] (∆π )*gravitational pull*magnetic thrust accelerator* times speed of light.. doodd

Fantastic writeup and video, thank you and well done!

It sounds like the Raptor will eventually have a thrust-to-weight ratio greater than 200….

because of the starhopper mission. check it in youtube

Thanks for taking the time to make this stuff. One correction: BE-4 is being designed for 100 flights not 25. The ’25’ values is for New Glenn vehicle, not the engines. This was discussed at the 34th Space Symposium (2018) by Bob Smith and also mentioned by Ariane Cornell.

Merlin is also designed for 100 flights, but it needs refurbishment after 10 so he used only 10 for Merlin. I doubt BE-4 can go all 100 flights without it.

Whether or not any of the engines might need refurbishment, and to what extent, is irrelevant and unknown for the new engines at this stage; The values are reflecting on “Reusability”.

if you’re quoting the aspirational re-use numbers for one new engine, then you should use that same metric for the other one too, else your comparison is somewhat flawed. Whether or not they achieve this in active service is another thing. Ultimately, if 100 is the stated goal for BE-4 (which it is), then why then would you use 25?

Anyway, thought I would bring this to Tim’s attention as he stated in the video that things will change and that he’ll update this website with the latest information.

BTW, in relation to some of the comparisons, I do appreciate that there’s going to be both assumptions and conjecture – some things are simply unknown at this stage.

BE-4 will likely require less pampering than Merlin just from the choice of fuel. CH4 doesn’t coke like RP-1.

How can the Be-4 be better than raptor?

If Be-4 would be 100 missions, than i guess raptor would be something like 500 missions

Tiny typos: it’s -> its

The LOX tank is MUCH smaller than it’s fuel tank.

And compared to Hydrogen, it’s fuel tank would be 3.7 times smaller.

bringing it’s potential cost down to just $1,414 : kN,

For interplanetary trips, methane makes the most sense because it’s boiling point

Ahh I came here to point out the it’s thing. Although you could argue that grammatically it makes sense either way.

Fathom?! I groaned!

I read about at least one manned Apollo mission where they had to shut down one of the F1 engines before reaching orbit, because (IIRC) it had started a pressure oscillation.

So, I don’t think we can claim 100% for F1. Also, they used a bunch of them on each mission, so the number flown seems like it should be much higher than 17.

But this was a fascinating and impressively thorough analysis of design tradeoff in rocket design. I learned more than I could have hoped, and the presentation was clearer than I have encountered anywhere else. So, thank you! I will be watching for future installments.

Yeah didn’t the middle rocket fail in Apollo 13? I think I remember that from the movie. They just moved the fuel to the other rockets and it was ok.

Apollo could not move any propellants. It was not the middle of the rocket (whatever that would be), it was the very top of the rocket. The Saturn V rocket had 3 stages, and on top of the 3 stages was the Command Service Module (CSM). Command (C) is the capsule, the SM is the small rocket underneath. Between the CSM and Saturn Stage 3 (oddly called S-IVB) was the 2 stage Lunar Excursion Module (LEM). Those 2 stages were the Ascent Stage on top, and the Descent Stage below. The CSM separates, then pulls the LEM off stage 3, then they leave stage 3. So at the time of the explosion, the CSM was docked to the LEM. In order (one side to the other of the line of parts): SM-C-AS-DS. The crew occupied the 2 in the middle, the SM and DS were just equipment/engines/propellant.

It wasn’t F-1, it was a J-2 Engine from the second stage

Saturn V:

First stage: 5 F-1 engines (Rp-1)

Second stage: 5 J-2 engines (Hydrogen)

Third stage: 1 J-2 engine (Hydrogen)

Tim explained that the Apollo 13 failure was a J-2 problem not a F-1 engine in another video (i forgot the name).

Yes, 2 second stage J-2 engines shut down on a couple of flights, one on Apollo 6 and one for Apollo 13. The J-2 engine isn’t an F1 so the engine failure statement can stand, although if the mission had failed I wonder if the mission failure would be counted against the F1.

You are thinking of the J-2 engines in the second and third stages of the Saturn V.

My mistake! One of the five J-2s in the second stage of Apollo 13’s launch vehicle was shut down early. They burned the other four for a bit longer, to compensate for its loss, successfully.

On the Apollo 6 test flight one outboard F2 engine failed and a second was shut down by the computer because its wiring was accidentally crossed with the failed engine. These were second-stage engines and the anomaly happened about four minutes into the second-stage burn. Actually, it would have been interesting to see the hydrogen-fueled F2 engines, third-stage examples of which were throttleable, included in this comparison.

So, in fact, the first-stage F1 record was essentially perfect.

Whoops- J2, not F2…

Apollo 6 had massive pogo oscillation in 1st stage. It was unmanned but if there was a crew the crew would have not survived . The J2 engine failure on the second and third stages was due to damage caused by the pogo oscillation. The oscillation almost cause an automatic abort and almost caused a structural failure of the 1 and 2nd interstage. While apollo 6 did make it to orbit the planned 3rd stage restart didn’t happen due to the damage to the J2. NASA had to redesign the 1 engine support and make some piping changes to prevent the Pogo oscillation.. The failure of the J2 was traced to a pipe that broke on due to the vibrations. In all future flights the J2 had a bend in the pipe so that any vibration would cause it to bend instead of breaking.

Where does the 17 missions numbers comes from for F1 ? Unless I’m mistaken, Saturn V only flew 13 times…

Saturn 1 used single F-1 engines

No, Saturn I (and IB) used 8 H-1s as first stage. The F-1 was used only in Saturn V.

No… Saturn 1 used 8 H-1 engines.

F-1 was used in Saturn V only.

Hey Tim, a lot of amazing info there!

The video is awesome and it’s really great you took the time to set up the website to have these things updated/corrected. Everything is explained in a very simple way, but I don’t see any rough simplifications to achieve that, which is amazing.

I have a few questions/suggestions:

1) You didn’t mention the expander cycle. Is that on purpose?

2) Your table for the price/reusability/reliability has a few things that look a bit strange to me. First, Did you use flight record as the number of missions flown with each engine? Wouldn’t it make more sense to use the number of engines flown? After all, if you are looking for reliability, each engine counts. In the same row, I don’t think the Saturn V flew 17 times. Wasn’t it 13?

3) It may be worth mentioning that the RS-25 is reusable, but will be used as expendable in SLS (such a shame!)

4) Just a curiosity. Do you know if the TWR of the RD-170 was better than the RD-180, given it had kind of the same turbopumps, just with more combustion chambers?

Answering for Tim:

1. He mentioned that he would discuss engines like the RL-10 in another video. This video was about cycles that lead up to the core subject, the full-flow staged combustion Raptor.

2. Saturn V did not just fly to the moon. There was also the Skylab launch and a few other things.

I’m including the Skylab and uncrewed tests of Saturn V in these 13 launches.

the others are correct – 13 flights of the Saturn V. Confirmed by Wikipedia, Apolloarchive.com, and Nasa’s history website (both links via wikipedia).

Saturn V rockets SA-501 to SA-512 for Apollo 4 through Apollo 17, and SA-513 for Skylab 1. Others were built but are now museum display pieces: SA-500F was the non-flight test article for fit and integration and SA-514 and SA-515 were never flown.

The expander cycle is not mentioned in the text (as far as I can tell) but the first black and white diagram of a rocket engine in this article appears to be from the Pratt & Whitney RL10A-3 Design Report, which is an expander cycle rocket engine.

How does the Raptor solve the coking problem in the fuel rich pre burn chamber?

That is just the chemistry of methane/oxygen. It probably starts with the fact that methane (CH4)

has no C-C bonds. RP-1 and diesel have carbon chains, some of which aggregate into soot during its (much studied!)

combustion. A great deal of diesel engine engineering revolves around minimizing this.

BTW, kudos to the author for a great article!

The raptor does not solve the coking problem. Using methane instead of RP1 solves the coking problem.

Methane burns producing CO2 and H2O. The coking problem with fuel rich RP-1 fuel engines arises because combustion products are lots of sooty, sticky hydrocarbons, not “clean” residue CO2 and H2O.

Using methane does not necessarily eliminate soot or coking. For example, see this research paper: https://www.researchgate.net/publication/224989842_LOXMethane_Technology_Efforts_for_Future_Liquid_Rocket_Engines

They allude to using special alloys or catalytic materials to prevent accumulation of soot in specific ducts or other surfaces. That said, the lack of C-C bonds helps immensely in the reduction of coking and soot.

Great job. Got me to subscribe. Came over after watching the latest Our Ludicrous Future. Thanks for all the hard work you put into the video!

Really nice video! Thanks for the big effort 🙂

One hint: RD-180 has 85 successfull launch (79 Atlas V + 6 Atlas III).

Greetings from Hungary!

Dude! Where are the sources you said you’d list? I need them for class! Please and thank you 🙂 Keep up the good work.

Rd-171 (rd-170 series) using on Zenit, fligth 84 times and 2 times rd-170 on Energia (4 engines each).

You shoud talk about rd-170 series.

Hi Tim, great article. However, you are wrong when you say that RD-170 barely ever flew. One variant of this engine is used in the first stage of the Zenit rocket (85 launches).

Yes, and its reusable. Tested for multiply fires and using.

Fantastic writeup and video, thank you and well done!

It sounds like the Raptor will eventually have a thrust-to-weight ratio greater than 200….

Also the Merlin 1D vacuum engine has an ISP of 311 which is 84% of the theoretical max ISP of 370 for a kerolox engine. So if the Raptor does the same or better it will have a vacuum ISP of at least 386.

It’s going to be very hard for anyone to make a better engine than the Raptor.

You should sell a poster of the types of engine cycles you discussed in the article/video.

Agreed!

>300 bar is like being 3 km deep in the ocean. I can’t even fathom.

Let me help here. A fathom is 6′ so 3000m is 1640 fathoms 🙂

Sorry, could not resist, an excellently researched and presented article/video!

You keep calling the source of hot gas for the turbine in a gas generator cycle engine a “preburner”, but this is not correct as the exhaust from the turbine is not burned again in a gas generator cycle engine. The source of hot gas for the turbine is properly called “the gas generator”.

What about the Vulcain II engines that powers the Ariane 5 rocket? Where does it fit in this picture?

The Vulcain engines are Hydrogen/Oxygen Gas Generator (open cycle) engines. They have a role similar to the RS-25 (Hydrolox first stage, supported by solid boosters), but being open cycle they are less efficient. It also has slightly less Thrust than the RS-25 and is not designed for reusability.

Just for completion, the Vulcain 2 has a Thrust of 1.36 MN, so pretty much halfway between the Merlin and the RS25. Just like the F1, the Vulcain 2 re-injects the fuel rich mixture from the gas generator into the nozzle for some extra power, helping it achieve close to 20% more than on the Vulcain 1.

Ariane 6 will use an evolution of the Vulcain 2 named Vulcain 2.1, which is slightly heavier, but drastically easier to build, making it both much cheaper and can be produced much faster. Since the slow production of Vulcain engines were the main reason why Ariane 5 could only fly about a dozen times per year, this could certainly help to give the rocket more flights, and by extension cheaper flights due to economies of scale.

You should have used the total number of engines times the number of flights to get a better indication of flights each individual engine has.

F1 – 5 engines per launch at 13 for a total of 65 engines used. ( I too am curious about the number 17 that was stated in the article)

Merlin 9 per launch at 71 for 639 engines to orbit (not even counting the vacuum version of the Merlin or the 27 per heavy falcon launched twice)

RD-180 1 engine at 79 for 79 engines to orbit

RS-25 3 engines at 135 for 405 engines to orbit

Really nice video! Thanks for the big effort 🙂

One hint: RD-180 has 85 successfull launch (79 Atlas V + 6 Atlas III).

Greetings from Hungary!

I had wondered about this and decided each approach has merit. Do it per LAUNCH gives a feel for the overall system reliability and reusability. Doing it per engine-flight gives an insight into the individual engine reliability and reusability and, in a broader sense. the engine design ‘maturity’. The analysis might benefit from showing both

He did use the engine count for the reliability numbers.

You are wrong in declaring RD engines not reusable.

“As part of a reusable transportation system, RD-170 was designed to fire as many as 10 times”. [1]

[1] http://www.russianspaceweb.com/rd170.html

I don’t believe he said that RD engines aren’t reusable — but that the *RD-180* engines aren’t reusable. The RD-170 is a whole different beast — and even then, I’m not sure where Anatoly’s note about RD-170 reusability came from. I don’t believe that the Energia itself could be re-flown, only the Buran orbiter it was built to carry.

I love this content, and if I could suggest one addition: A “Thrust per Cross Section Ratio”. The total thrust of the Raptor is so small compared to the F-1, but the Raptor is a whole lot smaller and designed to work in a larger cluster. In the space of 5 F-1’s SpaceX is going to fit 31 Raptors right? This ratio would give people a quick way of determining which engine, placed in a cluster to fill a up the bottom of a rocket, would have the most thrust.

Thank you so much for the video and the content. A suggesting for reporting on reliability is to not use success rate as a percentage, but instead use failure rate as a fraction. So 99.9% becomes 1/1000 failure rate, and >99.5% becomes <1/200 failure rate. Going from 99.8% to 99.95% is not very telling, but improving the failure rate from 1/500 to 1/2,000 is much more understandable, and you can immediately see that it is 4 times better. This way of reporting is common for systems that are highly reliable, such as in electronics and computing.

Why don’t they just…

If rocket science basically comes down to getting 2 substances in the combustion chamber in a controlled way, why don’t they just make a container with a motorized bottom panel that can slide in order to decrease the volume hence pushing out the propellant hence obliterating the need for complex pumping systems. But being a Belgian non-technical veterinarian I might overlook one thing or another. Anyways, with all that zero point energy around, the use of combustion chambers still seems so prehistoric….

I enjoy your show, keep up the good work ??

How would you supply the energy required to slide that “bottom panel” against a huge weight of propellant/oxidizer?

Remember that the pumps are on the order of 10,000HP (7.5 MJ/s).

Also, nobody has developed any practical use of ZPE.

There are a lot of parts shown in this (https://everydayastronaut.com/wp-content/uploads/2019/05/Rocket-engine-diagram-1024×576.jpg) chart that diagrams an engine. I have some questions about it.

1) Is this a gas generator engine, or a full flow staged combustion engine? Tim’s diagram of a gas generator is right below it, so I’m assuming it’s a gas generator, although I could be wrong.

2) Where can I find a complete explanation for how this engine works?

3) What model of engine is it?

It’s the RL-10 expander cycle engine. The image was used in Scott Manly’s video about expander cycle engines.

Loved the video. I know that you are thinking of writing about pollution by rocket engine in an upcoming video. I recall reading once that, after the first moon landing, the exhaust from the Lunar Excursion Module constituted 36% of the atmosphere of the moon. (The escape velocity of the moon is low, so Brownian motion caused the lighter molecules to zoom off the moon before long).

!Good afternoon, Len. I remember a series of articles by G. Harry Stein in the ’90s published in ‘ANALOG’ about McDonnell Douglas’ DC-X program and SSTO’s in general. One article was about commercial aviation and the similar potential pollution problem with an expanded SSTO Infrastructure . The conclusions were not good.

I’ve yet to find any copies of ‘ANALOG’ from 1993-1998 to verify or refute my sometimes foggy memory.

…going to be 66 in a couple days -still wana be like TIN-TIN and have my own rocket in the back yard…

“In order to keep the temperatures low, you can run the preburner at a less than optimal ratio, so either too much fuel known as fuel rich or too much oxidizer or oxygen rich.”

I believe that only the fuel rich scenario keeps exhaust temperature cooler. At least that’s the case in internal combustion engines.

No. Max temperature is reached at the optimal proportions of components. So both fuel and oxidizer rich (I sued to use argo – “sweet” and “sour” respectively) are cooler then optimal mix.

Huge work! Outstanding job!

Hard working Tim is aiding (helping) the cause of science and space exploration more than he probably is aware of (I bet or I imagine) by providing us with a platform of knowledge and kind discussion!

Many good things could be said of him (beyond his fans´s opinions) but to me he is above all a TEACHER! (in the sense of teacher-disciple relationship) MASTER OF SPACE EDUCATION!!!

We´ll always be grateful to his work!

Best wishes from Argentine Patagonia to all!

Willy Klein.

To whom this may concern.

Currently, I am working on a Chemistry Major Research Project that looks into the different types of fuels and their properties and an Engineering Studies Project that looks into different types of rocket engine systems and how they each operate relative to each other. I was wondering if you would be okay if I used the statistics from this report and if there was a place to find the original sources of these statistics. I thoroughly loved the video and it has fueled my curiosity in space exploration. Thank you very much for producing inspirational and educational content.

Ruairidh Granger

> “crazy high tolerance turbine blade”

Shouldn’t this say “low tolerance?”

Just for information — soviet RD-0120 – functional analogue of RS-25 (200 tf thrust, Energia 2-nd stage, LH2/LOX) had single shaft turbopump unit so soviet engineers managed to put 2 pump to the same shaft. Which is better for stability.

I believe that some copy errors have been made in generating the fuel comparison table shown in the video. Those who want to generate their own number can use the free or trial versions of RPA : Rocket Propulsion Analysis from http://propulsion-analysis.com/index.html. Alternately they can use https://en.wikipedia.org/wiki/Liquid_rocket_propellant and divide the exhaust velocities by 9.807 to get Isp.

I have done some calculations using a hypothetical engine with a chamber pressure of 30 MPa (similar to what the Raptor engine hopes to eventually run at) and an expansion ratio of 100. The expansion ratio is arbitrary – higher expansion ratios will give slightly higher Isp, but there is no “maximum” as it would be obtained only at an infinitely large expansion ratio.

I get the following results, presented in the order RP-1/Methane/Hydrogen

Optimum mixture ratio: Video 2.7 / 3.7 / 6, RPA 2.9 / 3.5 / 5.1

There is no real problem here. Around the optimum mixture ratio, the curve of Isp vs. mixture ratio is quite flat, and appreciable changes in MR make only tiny changes in Isp. Operational engines often pick a mixture ratio with slightly more oxygen than the theoretical optimum, as the difference in Isp is often very small and it is desirable to use more of the dense propellant to minimize tank sizes.

Isp Video 370 / 459 / 532, RPA 377 / 387 / 470

The video and the RPA calculation give similar results.

The video results for methane are far too high. All theoretical calculations show methane giving only a slightly higher Isp than RP-1. The video Isp of 459 for methane is roughly equal to the Isp of the best performing upper stage engines using hydrogen with very high expansion ratio nozzles (Shuttle RS-25 at 453).

The video results of 532 for hydrogen is way higher than any real world engine has accomplished, and more to the point is way higher than any theoretical calculation for a 100% efficient engine.

I suspect that the Isp of 459 for methane has been mis-copied from a reference which gave that value for hydrogen. Similarly I suspect that the value of 532 for hydrogen has been mis-copied from a reference which gave that value for a mixture of hydrogen and lithium burned with liquid fluorine, which is not what we are talking about here.

Great video

Would the organic hypergolic fuels that have been getting news lately be suitable as a primary propellant for putting cargo and possibly people in orbit?

What if we attach an electric generator to a turbine rotating by the preburner (using either an open or a closed loop) then feed the electricity to an electropump? This way we get rid of the complex valve system needed to control the turbopump. And we are free of the complexity of initially firing the system using a small battery to start the electropump and many more advantages.

not a rocket engineer but that sounds interesting would make starting the engine easier to one would think

I love this article as much as your YT video on the subject, and now that history has been made it is time to edit Raptor statistics as hop flight proven. Thanks for your work Tim.

Tim, thank you for this wonderful video, it is very informative! To be honest, I needed to watch it several times to be sure I understand you correctly 🙂

But after the Starhopper 150m flight test a few questions appeared. It was a pleasure to see a beautiful and clear exhaust from the engine, but I expected to see a single exhaust since Starhopper used a single Raptor engine and since Raptor is a full flow staged combustion cycle engine. What is a small dark (fuel-rich?) exhaust near the main exhaust?! It looked like an open cycle engine because of it. This exhaust is clearly seen in the SpaceX video https://youtu.be/bYb3bfA6_sQ?t=28

To me, and others, it appears to be a fuel leak. Such a leak accounts for the plume, flashes of flame at the same spot, the main exhaust anomalies at the end of the flight, and the apparent small fire around the engine compartment just as it landed. The escaping nitrogen COPV jetting away also fits with this scenario.

So, contrary to most I actually hold to a contrarian opinion that the open cycle is the superior option. Before I get quickly berated I will explain my rational first.

I will take for an example the F1 engine. Its turbo pumps produced 55000 bhp per engine to drive the pumps. However the engine itself can provide more than 33000000 hp each in equivalent thrust. So for the sake of 0.16 percent difference in trying to get a more efficient fuel burn for the turbines by a few percent out of that small 0.16 percent seems a rather waste. But that rather small percent is going to cost you a large heavily loaded turbine pump assembly that will require lots of engineering to work against the rather large and substantial back pressure of the combustion chamber. This will cost a lot in development cost, safety, extra weight and reliability. The weight differences can be seen in comparing the rather light Merlin thrust for weight in comparison with the others and also the the rather old (50 years ) F1 engine still compares well. And a system that can use a rather light far less heavily loaded almost off the shelf turbine technology. And the rather excellent reliability of those engine have shown too as a result.

The other thing I would like to note is the comparisons of different prospective fuels need to be measured as a complete system and not in isolation. So although Hydrogen is giving by far the best figures it has to be countered against the rather larger volumes required to store it and also against much higher pressure. This becomes a double whammy as not only are the fuel containers bigger they need to be thicker aswell to counter the extra pressure. Of course never mind the extra costs of storage and handling cryo fuels. This is where I think spacex has made the correct decision in using methane fuels.

All this being said however I am still a great fan of the original F1 engine, as it showed a rather exellent balance in design compromise and features. Being light weight, powerful and reliable. Designed at a time when money was thrown at the design to get it to work and developing new technologies it was still cost effective for that time. A person has to wonder what would be capable given modern materials and CAD design input what an updated one would look like.

As far as I understood the video, closed cycle engines are better for the following reasons:

* 2 turbines are rotating at precisely needed rpm, which results in the best possible pressure in the combustion chamber

* a substantial amount of fuel is wasted in the fuel-rich exhaust of the pre-burner of the open cycle engine

Therefore the thrust increase is significantly greater than 0.16% because of the more pressure in the combustion chamber.

The fuel consumption is better because the fuel is not wasted.

Btw, the F-1 engine actually uses pre-burner exhaust to increase the thrust: it is directed to the outer radius of the main exhaust: https://www.youtube.com/watch?v=BnIorwCudtw

Correction: F-1 pre-burner exhaust has been used mainly for cooling the nozzle, not for a thrust increase

Take a look at the documentary, “The Engines that Came In From the Cold.” The efficiency difference between closed cycle engines and open-cycle engines is ~20%. That is a very substantial number.

With the recent SpaceX success I found myself again thinking about what exactly SpaceX is up to with Raptor. With further reading and some calculations I realized the comparison tables above should include thrust-to-area ratio (where area is the footprint of the engine, or more precisely the minimum center-to-center dimension when packing multiple engines in a core).

The realization why is that your first fundamental constraint is F=ma (or F>mg). You need enough thrust to overcome gravity in a vertical launch (which is why current ion impulse engines are limited). The m here is the mass of a given fuel needed to take a single engine to orbit with a near zero payload (call it a 1lb payload just to keep it simple).

Why do I say this? Well you can always strap multiple engines together in a rocket to increase total thrust, but if thrust-to-area is too low you end up with a pancake like cone thing that’s unflyable. Or you can strap three cores together or launch multiple rockets separately but you cannot escape the F>mg constraint no matter what you do. It’s a fundamental parameter of the engine design.

Once you have lifted off only then Isp comes into play, that is a proxy for the “m” in my equation (mass of fuel needed to get 1lb into LEO). That’s fundamentally limited by the chemical potential in the fuel molecules giving you a minimum possible “m” for each fuel type (and explains why you need a reasonable amount of thrust per area to get to LEO).

So using today’s Wikipedia numbers, I get (using Sea level thrust in MN, diameter in m, with fuel type and sea level ISP in brackets)

RS-25 1.86 MN / (2.4m^2) = 0.32 (H2, 366 Isp SL)

RD-180 3.83 MN / (3.15m^2) = 0.39 (RP-1, 311 Isp SL)

F-1 6.77MN / (3.7m^2) = 0.49 (RP-1, 263 Isp SL)

Merlin 0.854MN / (1.25m^2) = 0.55 (RP-1, 282 Isp SL)

Raptor 2 MN / (1.3m^2) = 1.54 (CH4, 330 Isp SL)

Even accounting for the reduction in “m” associated with the lighter hydrogen fuel RS-25 is still the worst by this measure despite being theoretically the most efficient engine ever flown (maybe that is why it’s not flying?). It’s a different way to look at things – the RS-25 lacks enough thrust per unit area (which is why it needs boosters). You can fit roughly 3 Raptors for the same footprint as 1 RS-25 and launch four times the fuel mass that way, so any Isp advantage is completely wiped out. Plus CH4 is cheap and more dense so who cares if you carry extra fuel.

For interplanetary travel the equation is so exponential when you have to escape the gravity wells of two planets and have reasonable re-entry velocities that building a single one-time use vehicle that can do all that for a manned mission to Mars seems like it will never happen (never say never, but it may take infinitely long). SpaceX has figured that once you have about 100 tons to LEO, focus instead on cost and reusability. That way you can refuel on orbit, and fly a whole fleet including tankers, cargo and crewed vessels to Mars and beyond and either discard tankers as you go or make more fuel.

I learned a rule in systems engineering a long time ago, that when you have a number of parameters that have already been optimized to the 5-10% range assume they are all zero and re-examine your overall assumptions. It’s easy to get hung up optimizing these things (like thrust-to-weight, mass fraction, combustion efficiency) because they are hard problems but in the end it’s something else that gets you the win. Most of those are under 5% already so not that much to gain.

@Tim, @GreenMachine, love the video and love the follow up by Green Machine. Do you think you’ll add an update analysis Tim on the thrust-area-weight ratio? I like this analysis because with starship they’re strapping so many engines that wouldn’t be possible with any others described here.

This may explain why an open cycle methane engine would not work for starship.

My name is David

We have some updated numbers on the cost of the Raptors that contradicts the numbers you provided in your figure. Your illustration asserts that the Raptors are ~$2M each. Elon recently tweeted that they are “well below $1M each”. He also indicated that the goal was to get the Raptor 2.0 to ~$250k each.

Vvery nice work. I thought that on Apollo 13 the middle F1 had a failure.

On the F-1 being 100% reliable, which engine was that that cut out on Apollo 13? Or was it not even the engine’s fault?

No F1 engine was involved in the “Houston, we have a problem” problem on Apollo 13. That occurred 2 days after launch, so very separate from Saturn V and its F1 engines. Short version: the problem occurred when an oxygen tank for the fuel cells exploded. This was located in the Service Module.

Everyday Astronaut: Very, very excellent presentation. Thank you for the great job ! !

This is super useful, I went from knowing zero about the Raptor engine and rocket engines in general, to doing a research report about the Raptor engine for college. But I need more information: where can I find the documentation you used, values and detailed information about pre-combustion mixture rations, temperatures, turbopump efficiency and more?

Hi!

Awesome job!

One thing though: I don’t see any citations and to my experience different sources can give a little different numbers even though both can be completely reliable. I’m guessing you used the rockets’ user manuals?

I no longer have my Library of Chemistry, Space and Aeronautics, and most of my searches end up with no match or so many matches it’s like drinking from fire hose. What were the stats for a Methane/Hydrogen mix LOX mix? with Methane at it’s liquid point, how much Hydrogen can be dissolved or blended with Methane? I recall something that used this mix for a Mars/Moon return fuel made in situ. the hydrogen and methane coming from crew waste and waste water.

Hi!

And what about Aerospike Rocket Engines?

Can you make bring some light about them?

Thanks. 🙂

He has a whole different article/video about that.

@

https://youtu.be/D4SaofKCYwo

and

https://everydayastronaut.com/aerospikes/

Hello,

I am currently at college student working towards a degree in Aerospace Engineering. Your video inspired me to write a research paper on the topic of Full Flow combustion chambers for my Tech report class. I was hoping to find links to your resources in the Article version of your amazing presentation. I am wondering what sources you found the wealth of information you presented. I was hoping I could use those resources in my paper to help me convey the information nearly as well you have.

Please let me know if you an share a list of sources, Thank you!